Home > Food Processing > Fried Bugles Process Line

Fried Bugles Process Line

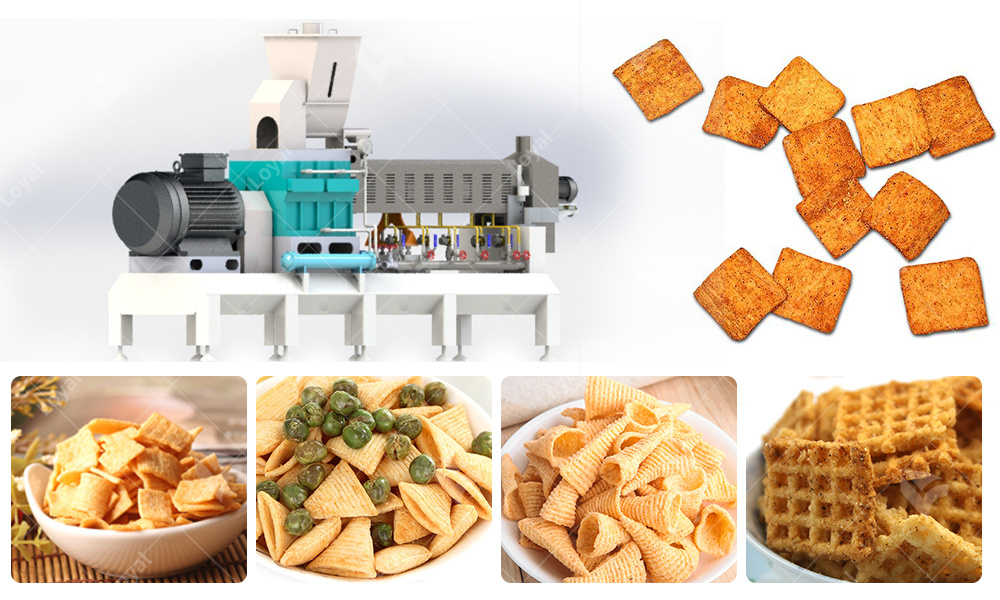

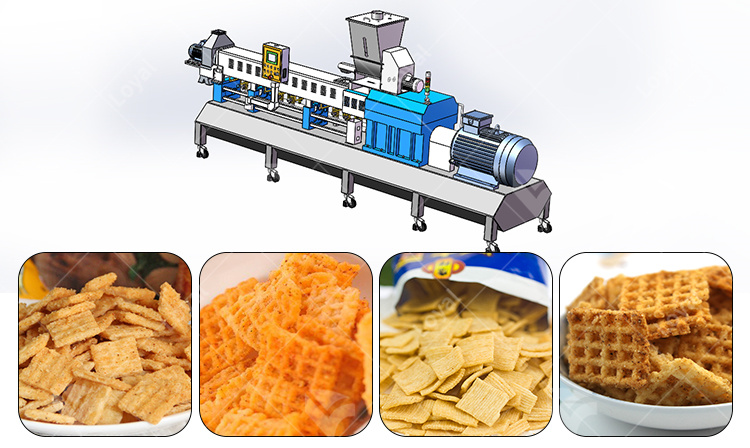

February 24, 2023Fried bugles process line uses twin screw extruding technique to replace the traditional steam boiling process.It includes mixing,extruding,shaping,frying and flavoring process,no needing boiler,with simple process,high efficiency and little pollution.The raw materials ccan be rice powder,corn powder,wheat flour individually or their mixture.Only by changing the moulds,shaping or cutting machine,the shapes can be various,like sticks,square sheet rib chips,diamond chips,wavy chips,pillow shapes and bugles etc.The taste is savory and not greasy.

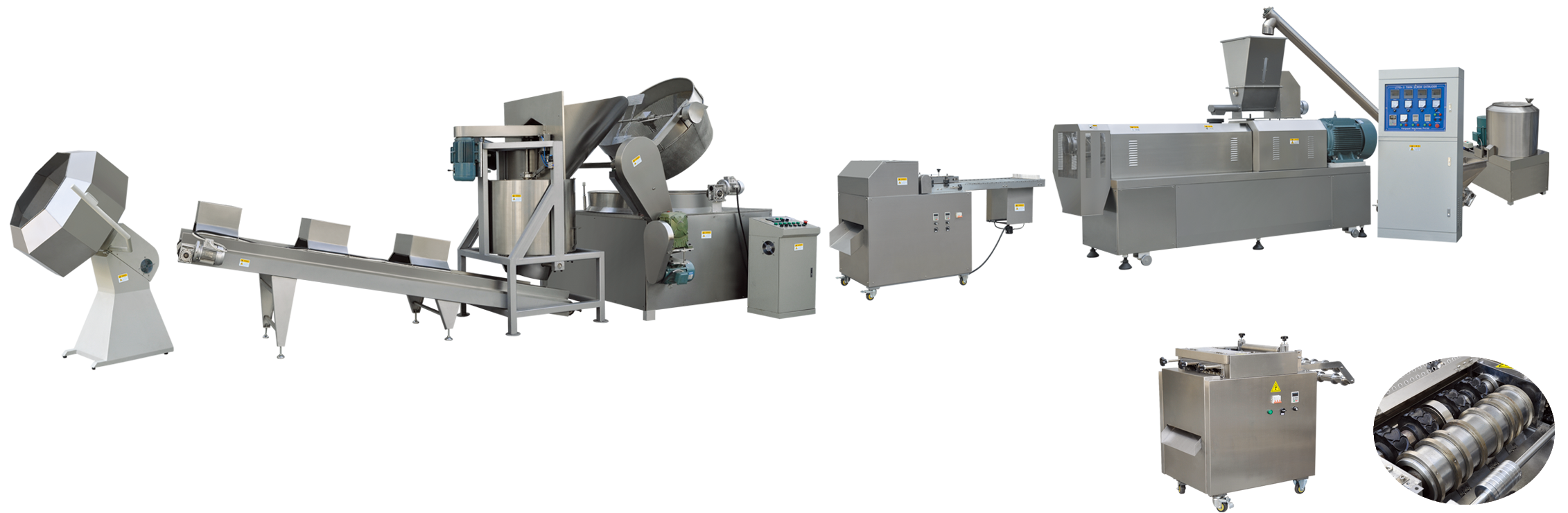

The Flowchart Of Fried Bugles Process Line

- Mixer--- 2. Screw Conveyor --- 3. Twin-Screws Extruder --- 4. Pulling And Cutting Machine --- 5. Bugle Shaping Machine --- 6. Hoister --- 7. Continuous Fryer --- 8. De-Oilling Machine --- 9. Hoister --- 10. Flavoring Machine

The Function Of Fried Bugles Process Line

- Mixer:Mixer makes the raw material adding to water and other chemical additive fully mixed.

- Screw Conveyor:Conveying the raw material from the mixer to the extruder.

- Twin-Screws Extruder:The dough is then fed into an extruder machine, which shapes it into the classic bugles curved shape. The extruder uses heat and pressure to shape the dough, and the resulting Bugles are cut to a specific length.

- Pulling And Cutting Machine:Used to change the shape of the product, adjust the product: wonderful crisp angle, crescent, triangle, fish shape, etc.

- Bugle Shaping Machine:Create the desired product shape

- Hoister:Used to enhance the product to reach the next device.

- Continuous Fryer:The bugles are then fried in hot oil to give them a crispy texture and golden color. The frying process typically takes place in a continuous fryer, where the bugles move along a conveyor belt through a bath of hot oil.

- De-Oilling Machine:Remove the oil on the outside of the bugles.

- Hoister:Deliver the snack to next device.

- Flavoring Machine:After frying, the bugles are sprayed with a seasoning mixture while they are still hot. This seasoning can vary depending on the flavor of the bugles being produced.

- Cooling And Packaging:The seasoned bugles are then cooled and dried to remove excess oil and moisture. Once they are cooled, they are packaged in bags or containers and sent for distribution.

The Parameter Of Fried Bugles Process Line

| Model | Installed Powder

(kw) |

Powder Consumption

(kw) |

Output

(kg/h) |

Size

(L*W*H) |

| LY65 | 92kw | 64kw | 180-200kg/h | 19000*2300*2200mm |

| LY70 | 111kw | 78kw | 200-250kg/h | 20000*2300*2200mm |

What’s Advantage Of Fried Bugles?

| Crispy texture | Frying bugles can give them a crispy and crunchy texture, which some people may prefer over the softer texture of non-fried bugles. |

| Enhanced flavor | Frying bugles can enhance their flavor by giving them a slightly caramelized and savory taste. This can be particularly appealing for those who enjoy savory snacks. |

| Versatility | Fried bugles can be a versatile snack that can be enjoyed on their own or as a component in other dishes. For example, they can be crushed and used as a crunchy topping for salads or soups. |

| Portability | Fried bugles are a relatively portable snack that can be easily packed and taken on-the-go. They also have a relatively long shelf life, which can make them a convenient snack to have on hand. |

The Advantage Of Fried Bugles Process Line

| Consistent Quality | Fried bugles process line ensures that every bugle snack is produced using the same recipe and under the same conditions. This results in a consistent quality of bugles snacks, which is essential for building a loyal customer base. |

| High Production Capacity | Fried bugles process lines can produce a large number of bugles snacks in a short period of time. This is important for meeting the high demand for bugles snacks, especially during peak seasons. |

| Efficient Production | Fried bugles process line can automate most of the manufacturing process, which results in a more efficient production process. This reduces the need for manual labor, lowers the production costs, and increases the overall productivity. |

| Customization | Fried bugles process lines can be easily customized to produce different types of bugles snacks with different flavors, shapes, and sizes. This enables manufacturers to cater to the changing tastes and preferences of their customers. |

| Longer Shelf Life | Fried bugles have a longer shelf life compared to their non-fried counterparts. This is because the frying process removes the moisture from the snacks, making them less susceptible to spoilage. Fried bugles process line ensures that the frying process is carried out under controlled conditions, which further extends the shelf life of the snacks. |

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan