Home > Food Processing > Gelatin Drying Microwave Oven

Gelatin Drying Microwave Oven

April 26, 2023Description Of Gelatin Drying Oven

A gelatin drying oven is a machine used in the gelatin manufacturing process. The oven provides a controlled environment for gelatin to dry, removing excess moisture and stabilizing the product. Ovens usually have a series of racks or trays on which the gelatin is placed to dry. The oven is heated to a specific temperature and the gelatin is dried for a certain amount of time until the desired moisture content is reached. The drying process is critical to the quality of the final product, as under-drying gelatin can spoil, while over-drying gelatin can cause it to become brittle or lose its texture. The oven can also be equipped with an air circulation system to ensure consistent and even drying of each tray. A gelatin drying oven is an essential tool in the gelatin production process, helping to produce a consistent, high-quality product.

How To Dry The Gelatin

1.Prepare Gelatin: Mix gelatin powder with water to form a homogeneous solution. Gelatin should be heated to a temperature where it can be completely dissolved.

2.Pour The Gelatin:Pour the gelatine solution into the selected container or tray. The container should be flat to aid in the drying process.

3.Place In The Oven:Place the container in the oven, or place it on a tray if it is not already on.

4.Set The Temperature:Set the oven temperature to around 140-160°F or 60-71° The temperature should be low enough to avoid cooking the gelatin, but high enough to dry it out.

5.Open The Door Vent:Open the door vent of the oven to allow the airflow needed for the drying process.

6.Check The Gelatin:Check the gelatin from time to time and use a thermometer to maintain the set temperature. Stir the mixture once or twice to ensure even drying.

7.Test For Doneness: Use a cake tester or toothpick to check if the gelatin is dry enough. If it comes out clean, the gelatin is dry.

8.Out Of The Oven:After the gelatin sheet is completely dry, take it out of the oven and let it cool down to room temperature.

9.Cut Into Pieces And Store:Cut the gelatine into desired shapes and store in a cool, dry place with low humidity.

Following these steps will help you dry gelatin efficiently and effectively using a drying oven.

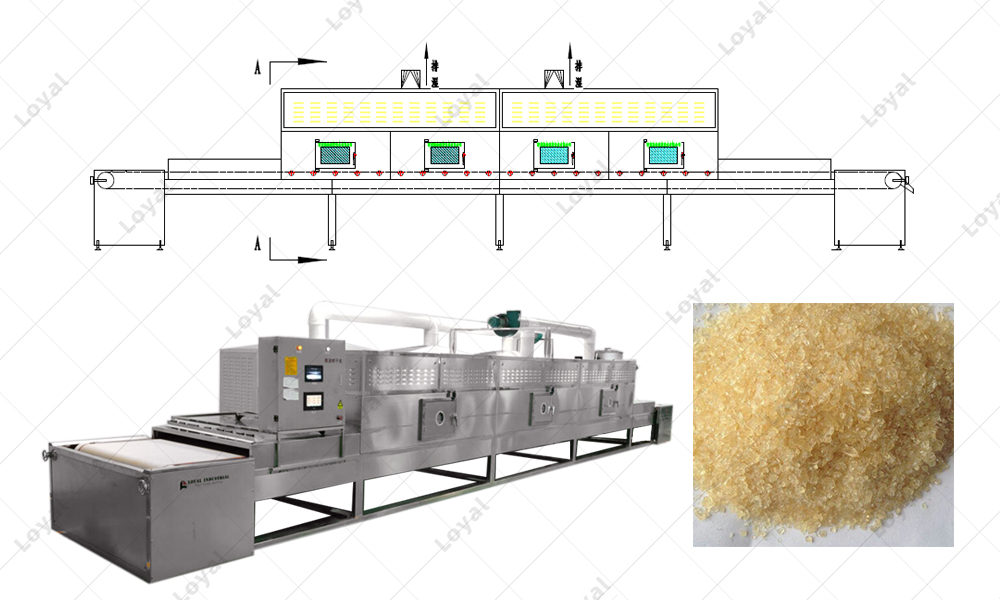

Working Principle Of Industrial Microwave Gelatin Drying Oven

Industrial microwave gelatin drying ovens use electromagnetic radiation in microwave mode to heat and dry gelatin. This drying method is faster and more energy efficient than traditional drying methods. The oven has a cavity that contains a waveguide and magnetron to generate microwave radiation. The cavity is a closed box that does not allow microwaves to escape, thus creating an even heating environment. Put the gelatin in a tray or container and place it in the cavity. Microwaves penetrate the clear gel material and excite water molecules, causing them to vibrate and heat up. This heat is transferred to the surrounding material, causing the water to evaporate and the gelatin to dry out. The oven is equipped with a control system that regulates the temperature and time of drying, ensuring consistent and efficient results. After the drying cycle is complete, the gelatin is removed from the oven and allowed to cool before storing. Overall, industrial microwave gelatin drying ovens provide a faster, more efficient, and more precise method of drying gelatin compared to traditional methods. It is ideal for large production facilities where high quality, uniform results are required.

Microwave Gelatin Dryer's Advantage

| Faster Drying Time | Microwave drying is faster than traditional drying methods, because the excitation of water molecules makes the water evaporate quickly. This reduces overall processing time and increases productivity. |

| Uniform Drying | Microwave radiation evenly penetrates the transparent rubber material to ensure that the entire material is dried uniformly. This eliminates the risk of over- or under-drying that could affect the quality of the gelatin. |

| Energy Saving | Compared with traditional drying methods, microwave drying uses less energy. This is because the microwave radiation directly heats the water molecules, reducing the amount of heat lost to the surrounding environment. |

| Improve Product Quality | Compared with traditional methods, microwave drying is a gentler process, which helps to maintain the quality and nutritional value of gelatin. It also reduces the risk of contamination, as the closed cavity keeps contaminants out. |

| Reduce Labor Costs | Industrial microwave gelatin drying ovens are automated and require minimal supervision. This reduces the need for manual labor, resulting in significant cost savings. |

Overall, industrial microwave gelatin drying ovens provide a faster, more efficient, and more precise method of drying gelatin compared to traditional methods. It is ideal for large production facilities where high quality, uniform results are required.

Gelatin Product Display

Gelatin is a protein-rich substance derived from collagen and found in animal skin, connective tissue and bones. It is a common ingredient in many foods, including desserts, candies and snacks, and is also used to make capsules, coatings and other medicinal products.

Gelatin is produced through a process called hydrolysis, which involves the use of heat and acid to break down collagen into smaller molecules. The resulting gelatin is a viscous, colorless, odorless substance that is soluble in hot water but insoluble in cold water.

There are different types of gelatin available, including:

1.Type A gelatin: This gelatin is derived from acid-treated animal tissues, such as pig skin and bones.

2.Type B gelatin: This gelatin is derived from alkali-treated animal tissues, such as bovine hide and bovine bone.

3.Kosher Gelatin: This gelatin is extracted from fish bones or cowhide processed according to strict Kosher dietary laws.

Gelatin has several functional properties, including gelling, foaming, stabilizing and binding, which make it an important ingredient in many different food products. It is also used in the pharmaceutical industry as a coating for capsules and tablets.

However, some people may be allergic to gelatin, and it's not suitable for vegetarians or vegans because it comes from animal sources.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan