Home > Food Processing > Glass Fiber Drying Microwave Oven

Glass Fiber Drying Microwave Oven

April 22, 2023Description Of Glass Fiber Drying Oven

Fiberglass drying oven is a special equipment for manufacturing glass fiber products. Fiberglass is a lightweight, strong and versatile material used in everything from insulation to automotive components. Drying ovens are used to eliminate any moisture that may be present in the glass fibers prior to further processing. Moisture can weaken the fiber and reduce the quality of the final product, so it is important to dry the fiber thoroughly before moving on to the next stage. An oven is usually a large enclosed space with a series of heaters and fans that circulate hot air around the fiberglass. Temperature and airflow are carefully controlled to ensure that the fibers dry evenly at the optimum temperature. Fiberglass is usually placed on a tray or rack and loaded into the oven. The fibers are left to dry for a specific amount of time, depending on the type of fiber being processed and the conditions in the oven. Once the fibers are dried, they can be further processed into a wide range of products such as insulation, composites and reinforcements for plastic and rubber products. Using a fiberglass oven helps ensure these products are of the highest quality and meet strict industry standards.

How To Dry The Glass Fiber

1.Prepare the fiberglass: Make sure the fiberglass is clean and free of any contaminants before placing it in the oven. If necessary, use a towel or compressed air to remove excess moisture from the fibers.

2.Load the fibers into the oven: Place the glass fibers on a tray or rack and load them into the oven. Make sure the fibers are evenly distributed and not too dense as this will interfere with the drying process.

3.Set the temperature: Set the oven to a temperature appropriate for the type of fiberglass being processed. The temperature is usually in the range of 150-200°C, but may vary depending on the type and thickness of the fiber.

4.Set the timer: Set the timer for the desired drying time. This will vary depending on the thickness and moisture content of the fiber as well as the temperature and airflow of the oven.

5.Monitor the drying process: Check the fiberglass regularly to make sure they are drying evenly and not overheating. If necessary, adjust oven temperature or airflow to achieve desired drying conditions. 6. Removing the fibers: After the drying process is complete, remove the glass fibers from the oven and allow them to cool before further processing.

By following these steps, you can effectively dry glass fibers using a drying oven to ensure they meet the desired quality standards for your final product.

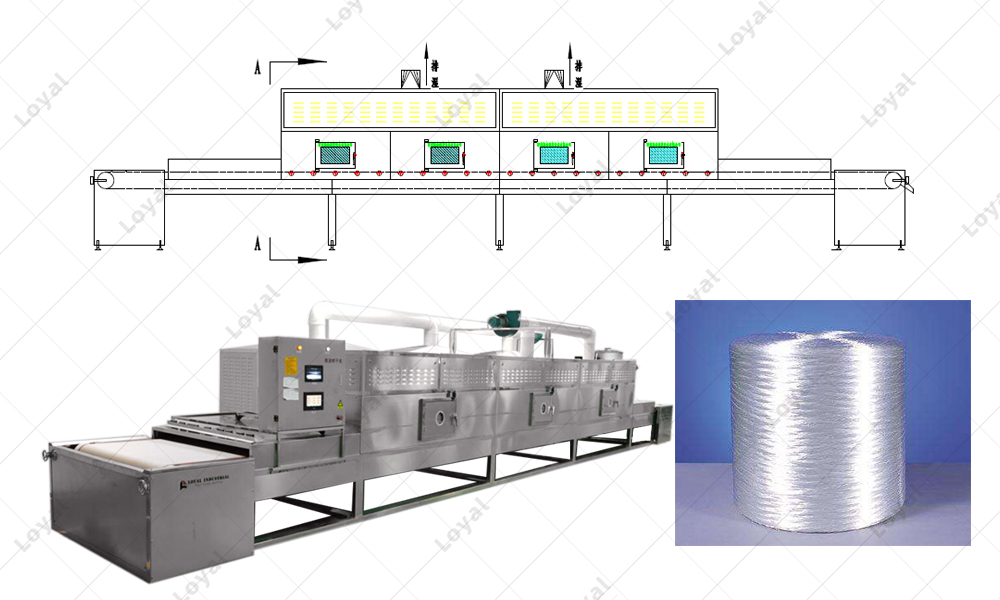

Working Principle Of Industrial Microwave Glass Fiber Drying Oven

The industrial microwave fiberglass drying oven works on the principle of microwave energy heating. It uses electromagnetic waves in the frequency range of 300 MHz to 300 GHz to generate heat within the glass fibers, causing the moisture present in it to evaporate. In microwave ovens, fiber trays are placed in an oven and exposed to high frequency electromagnetic waves. Microwave energy is converted into heat energy immediately upon contact with the fiberglass material. The moisture present in the fibers absorbs this thermal energy and evaporates. Microwave drying oven is composed of magnetron, transformer, waveguide and cavity. Magnetrons generate microwave energy and convert it to higher frequencies. A transformer further boosts the voltage and current to supply the cavity. A waveguide guides the energy generated by the magnetron into the drying chamber where it is absorbed by the glass fibers. The temperature in a microwave oven is controlled by adjusting the power and duration of the microwave energy. The drying process can be precisely controlled to meet the specific needs of different types of glass fibers. The advantages of using a microwave oven include faster drying times, higher product quality and energy efficiency. Compared with traditional drying methods, microwave drying can reduce drying time by up to 90% and save a lot of energy.

Microwave Glass Fiber Dryer's Advantage

The industrial microwave fiberglass drying oven works on the principle of microwave energy heating. It uses electromagnetic waves in the frequency range of 300 MHz to 300 GHz to generate heat within the glass fibers, causing the moisture present in it to evaporate.

In microwave ovens, fiber trays are placed in an oven and exposed to high frequency electromagnetic waves. Microwave energy is converted into heat energy immediately upon contact with the fiberglass material. The moisture present in the fibers absorbs this thermal energy and evaporates.

Microwave drying oven is composed of magnetron, transformer, waveguide and cavity. Magnetrons generate microwave energy and convert it to higher frequencies. A transformer further boosts the voltage and current to supply the cavity. A waveguide guides the energy generated by the magnetron into the drying chamber where it is absorbed by the glass fibers.

The temperature in a microwave oven is controlled by adjusting the power and duration of the microwave energy. The drying process can be precisely controlled to meet the specific needs of different types of glass fibers.

The advantages of using a microwave oven include faster drying times, higher product quality and energy efficiency. Compared with traditional drying methods, microwave drying can reduce drying time by up to 90% and save a lot of energy. Additionally, the process is uniform and results in a consistent level of moisture content throughout the material, reducing the risk of overheating, under-drying, or uneven drying.

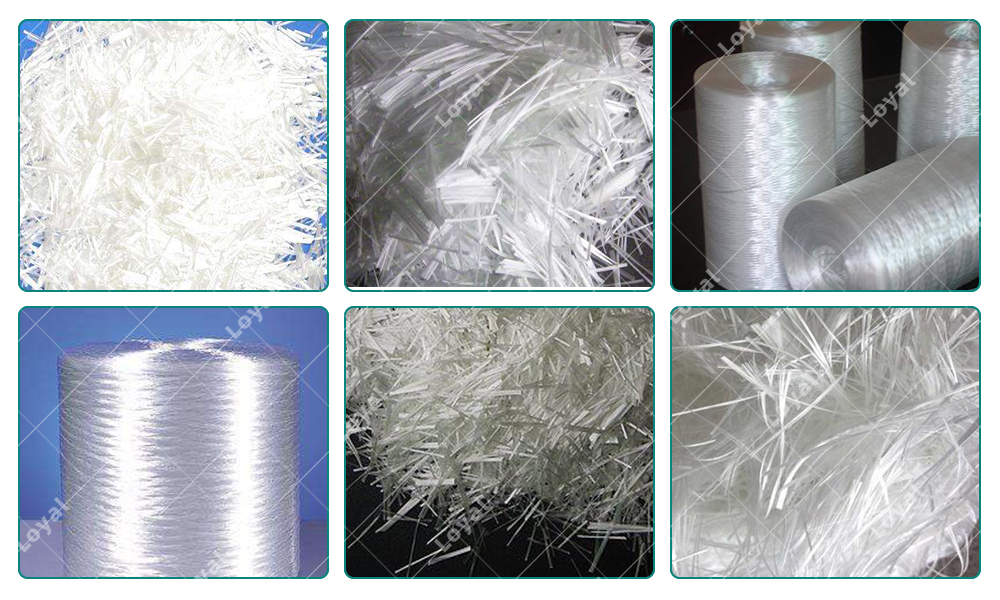

Glass Fiber Product Display

| Fiberglass Reinforcement | Used to reinforce composite materials used in construction and other applications, such as fiberglass. |

| Fiberglass Insulation | This type of insulation is made from fiberglass to form a mat, which is then used to insulate walls, ceilings, and floors. |

| Glass Fiber Filters | These filters are used in industrial applications to filter liquids and gases. |

| Fiberglass Fabrics | These lightweight, durable fabrics are used in a variety of applications including apparel, outdoor gear, and aerospace. |

| Fiberglass Cables | These cables are used in industries such as telecommunications to transmit data and power. |

| Fiberglass Composites | These materials are made by combining fiberglass with a matrix material such as resin, resulting in strong, lightweight materials used in a variety of industries. |

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan