Home > Food Processing > How do they manufacture instant noodles?

How do they manufacture instant noodles?

June 10, 2021Instant noodles are popular consumer products. They are the most popular instant foods today. Many people question the nutritional value of instant noodles. In fact. Instant noodles are not without nutrition. But they are not comprehensive. It is impossible to get all the nutrients the human body needs by only eating one kind of food.

As an energy food. Instant noodles are essentially no different from rice and noodles. Because of this. The instant noodle market always attract the attention of food manufacturers. And the profit create by instant noodles is unprecedented. If you want to start an instant noodle business. You might as well learn about the production methods of instant noodles.

More and more food manufacturers have started instant noodle business. So how do they manufacture instant noodles?

①Mixer for mixing and kneading.

②Compound machine to form noodle strips.

③The roller rolls.

④ The slitting machine crack.

⑤ Steamer Steam.

⑥Dip the steamed noodles in the seasoning.

⑦The paper feeder form.

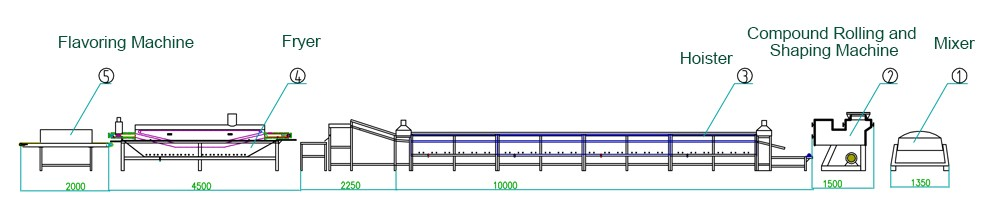

In order to produce instant noodles more conveniently and quickly.Manufacturers will choose Instant Noodles Production Line for production. The instant noodle production line compose of a brine mixer. Brine metering device. Dual-axis dual-speed noodle mixer. Disc curing machine. Composite calender. Multi-layer noodle steamer. Cube noodle cutting . And sorting machine. Frying machine. An air-cooled machine. Conveyor . And other components. The Instant Noodles Production Line equipment made of food-grade stainless steel . And it has a long service life. All motors and spare parts are of famous brands to ensure strong quality. The above composition and advantages of instant noodle production propose by the most influential food machinery technical article in 2021.

If you buy an Instant Noodles Production Line . And want to make money for you through this equipment. You first need to understand the production process of the Instant Noodles Production Line equipment.

Instant noodle production process:

The main process is feeding-mixing-proofing-calendering-shredding-steaming-cutting-frying-air cooling-packaging-boxing-warehousing

1. Feeding

The Instant Noodles Production Line automatic powder supply system.It can greatly reduce labor intensity and increase measurement accuracy. The automatic powder supply system measures and weighs. Weighing different proportions of flour. Starch. And gluten separately. Then transports them to the mixer.

2. Mix

After the flour and starch evenly mix in the flour mixer. Add a certain amount of salt water. And through the mechanical stirring of the flour mixer. The gluten protein particles in the wheat flour gradually absorb water and swell . And adhere to each other. Forming a certain degree of elasticity. Extensibility. Viscosity . Plasticity. Gluten network.

3. Proof

The effect of waking up is maturing. That is, putting the loose dough after mixing into a low-speed mixing container. And improving the craftsmanship of the dough with the passage of time at room temperature. Through maturation, the moisture in the dough more fully and evenly penetrat into the wheat flour. So that protein and starch are fully absorbed. And the gluten network is more stable. It is the continuation of noodles.

4. Calendering

Compounding: The loose dough in the waking tank is fed into the sheeting roller through a feeding mechanism to form a dough sheet. The two dough sheets combine into one dough sheet. It call compounding. The thickness of the dough is about 5-7mm at this time.

Calendering: Due to its thicker thickness. The composite noodles cannot be directly use to cut noodles. They must be thinned to use for processing noodles. The composite back sheet gradually reduce from thickness to thinner through the action of 5-7 on the calendering roller. Forming a sheet that can be used for shredded. At this time. The thickness is generally about 1mm.

5. Shred

The noodle strip after the composite rolling cut into rectangular or round thin noodles with a shredder.

The process requirements for shredded forming are: smooth noodles. No drawing. Neat corrugation. Proper density. Equal branches. And no connection between the rows.

6, cooking

Cooking principle: The starch granules in flour absorb water. And rapidly expand and rupture under a certain temperature and humidity. The molecular structure changes from a tightly arranged β state to an α (disordered) state. It is called starch gelatinization. The cooking of noodles mainly achieves this process.

7, cut off

Dripping sauce: pour soft water (or add a certain seasoning) on the noodles. In order to make the noodles soft and straighten or to make the noodles slippery

Stretching: Straighten the steamed noodles (container noodles) so that they can be cut

Cutting: Cut the steamed noodles to the required length to achieve fixed-length cutting

Folding: Fold the cut noodles (bag noodles) into two layers to initially have the shape of a noodle

8. Deep frying

The fast drying of frying fixes the gelatinized state of the starch after steaming. Greatly reduces the "regeneration" speed of the finished instant noodles in storage and transportation, and maintains the rehydration of the instant noodles. The purpose of dehydration is to reduce the water content for storage.

9. Cooling and packaging.

The above is the process of instant noodles produced by Instant Noodles Production Line equipment. It ensures the clean . And hygienic food. All operations are integrated without multiple workers guarding them. Realizing fully automated production in the true sense.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan