Home > Food Processing > Industrial Macaroni Pasta Making Machine

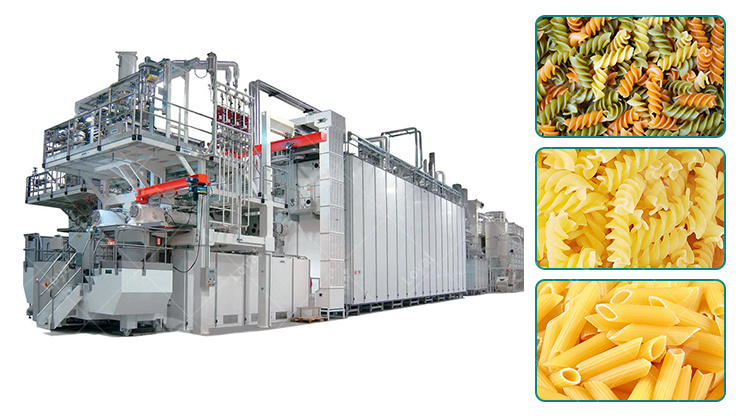

Industrial Macaroni Pasta Making Machine

March 23, 2023Pasta extruder making machine uses corn starch and potato starch as the main raw materials. And macaroni pasta machine uses a unique extrusion molding process to achieve the best sensory effect on the product shape. The product shape is natural and lifelike, the texture is delicate, the taste is loose. And it is not cracked or scattered. The pasta food making production line has reasonable design, strong stability and high degree of automation. The extruder adopts frequency conversion speed regulation technology, which is highly efficient and energy-saving. Precise parameter control and extrusion process ensure the stable quality of processed products. There are dozens of products to choose from, such as spirals, potato chips, shrimp cracks, shells, round tubes, sub-snails, circles, waves, and so on.

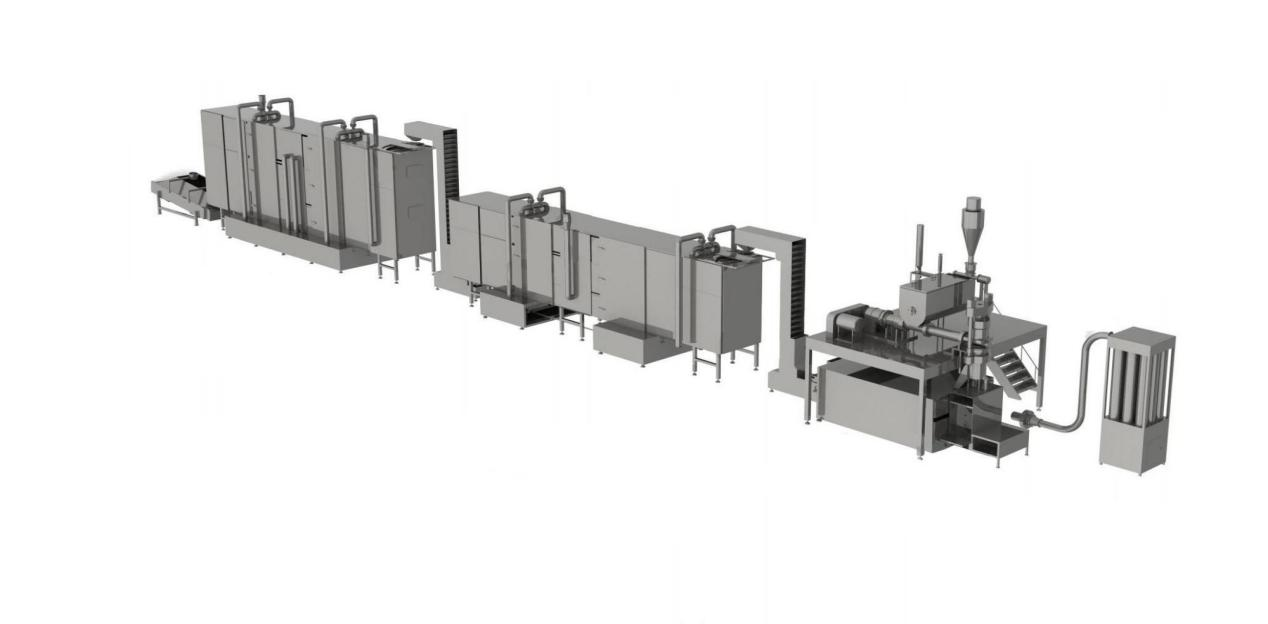

The Flow Chart Of Macaroni Pasta Process Line

1.Mixer2. Screw Conveyor 3. Single Screw Extruder With Cooling System 4. Pulling And Cutting Machine 5. Hoister 6. Drying Machine 7. Cooling Conveyor

| No. | Name | Function |

| 1 | Mixer | Mixer makes the raw material adding to water and other chemical additive fully mixed |

| 2 | Screw Conveyor | Screw conveyor can not only convey on the level but also by any angel these materials can be conveyed in the stainless steel roller without leaking, dust pollution; meanwhile it can send the self-mixer to the feeding machine or the conditioner and directly send the discharge hole of the inflating extruder. |

| 3 | Single Screw Extruder With Cooling System | 1.Transmission Form:Motor directly connected to reducer Directly connected to reducer Directly connected to single screw.

2.The equipment's feeding system and extrusion system are all adjustable by frequency conversion control. 3.The machine is composed of feeding system, extrusion system, heating system, transmission system and control system. It adopts advanced screw extrusion technology and uses high temperature and high pressure to mature and expand the material into one-time completion. The host adopts frequency conversion speed regulation to ensure the stability of the production process. 4.The products are of various colors, varieties, beautiful appearance, natural and lifelike, delicate texture, and extensive use of raw materials. |

| 4 | Pulling And Cutting Machine | 1. The cutter is used to cut rectangular tubes and round tubes.

2. The pulling and cutting machine consists of two parts: the cutting system and the conveying system. 3. The machine is easy to operate, and the length of the frequency control is adjustable. 4. This cut is specially designed for macaroni |

| 5 | Hoister | Transport the pasta to the next machine. |

| 6 | Drying Machine | The oven is a multi-layer circulating drying box with good heat preservation effect and high efficiency and energy saving. |

| 7 | Cooling Conveyor | This equipment is used to transfer product from extruder to hoist. Products such as shells, spirals, and bends do not need a cutting machine. The conveyor directly transports the products to the hoist to fill the gap in the middle. |

Features Of Pasta Making Machine

| Mixer | 1. This part that contacts mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design, good seal and avoids leaking the material. |

| Screw Conveyor | 1. This part that contacts mixer to material adopts the stainless steel material.

2.Prevent accumulation of raw materials |

| Single Screw Extruder With Cooling System | 1. Use advanced frequency control skills, stable work and less power consumption;

2. The screw is made of alloy steel, which has a longer service life; 3. Automatic heating control system, easy to work and more accurate parameters. 4. The length of the screw increases the residence time and mixing time of the raw materials in the screw, and increases the maturity of the raw materials. 4. The equipment is equipped with a water circulation temperature control system. 5. Equipment feeding motor, host motor, using frequency conversion speed control. |

| Pulling And Cutting Machine | 1. This part that contacts mixer to material adopts the stainless steel material.

|

| Hoister | 1. The elevator conveys the food from low to high, according to the process; the drying box inlet determines the height and horizontal distance of the elevator

2. The conveying adopts food grade accessory, and the frame adopts all stainless steel material 3. The conveyor belt of the elevator is equipped with a leak-proof material retaining edge device. 4. The hoist feeds at a constant speed. |

| Drying Machine | The hot air drying box is professionally designed for nutritious rice after practical experience and product characteristics.

feature: 1. The oven has a compact structure, a small footprint, and is economical and applicable. 2.The mesh belt and guard plate are all made of food grade stainless steel to ensure that the materials used are qualified. 3. The operating speed of the oven is controlled by frequency conversion, smooth operation and long-term use. 4. The temperature is controllable, and precise temperature probes are installed in heating zones during heating to ensure that the temperature error is small and affect the product. 5. Heating method: heating tube. 6. Drying is equipped with a dehumidification system, which effectively discharges moisture and air. |

| Cooling Conveyor | 1. This part that contacts mixer to material adopts the stainless steel material. |

Parameter Of Pasta Production Line

|

Model Parameter |

LY 3000 | |

| Voltage | 380 V/50Hz,3 phase | |

| Instant Power | 150kw | 55kw |

| Actual

power consumption |

120 kw | 35kw |

| Certification | CE,IBV,ISO | |

| Capacity | 80-120 kg/h | |

| Diameter | 23000 X 1500 X 2600 mm | |

| Worker | Macarini: 1-2 | |

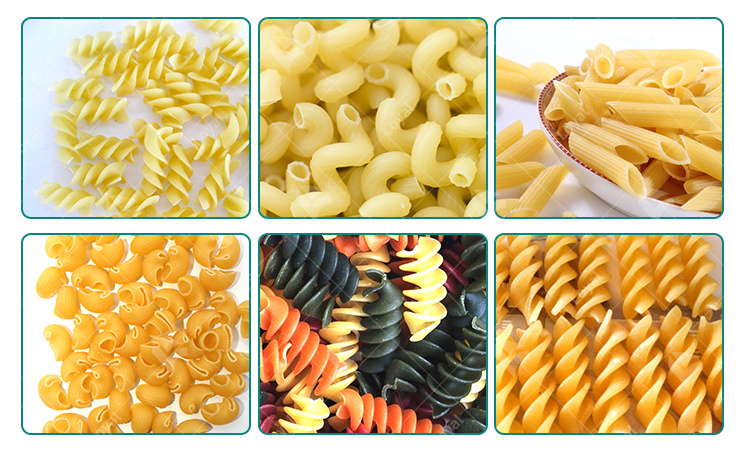

| This pasta food making machine line can use wheat flour as main material to make different shapes pasta , like tube , elbow , screw , shell etc .

If you want more big capacity, such as 200kg/h, we can customed according to your requirement. |

||

Features Of Industrial Pasta Making Machine

- Visible auto-temperature makes temperature controlling to be easier and more precise

- The pasta macaroni making machineare made by steel. The screw is made by alloy steel and special craft, so the screw life is longer.

- It's very popular food and many people like to eat the food.Because it not only tastes delicious but also it's very convenient and suitable to the step of the time

- Our mechanic will go to your country to teach your worker to operate the processing line until they can handle well

Raw Material Of High Quality Pasta Making Machine

Adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials.

Voltageof Industrial Macarons Making Machine

In China: Three phases: 380V/50Hz, Single phase: 220V/50Hz. We can make it according to customers' Local voltage according to different countries.

PASTA SAMPLES

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan