Home > Food Processing > Pet Chewing Food Process Line

Pet Chewing Food Process Line

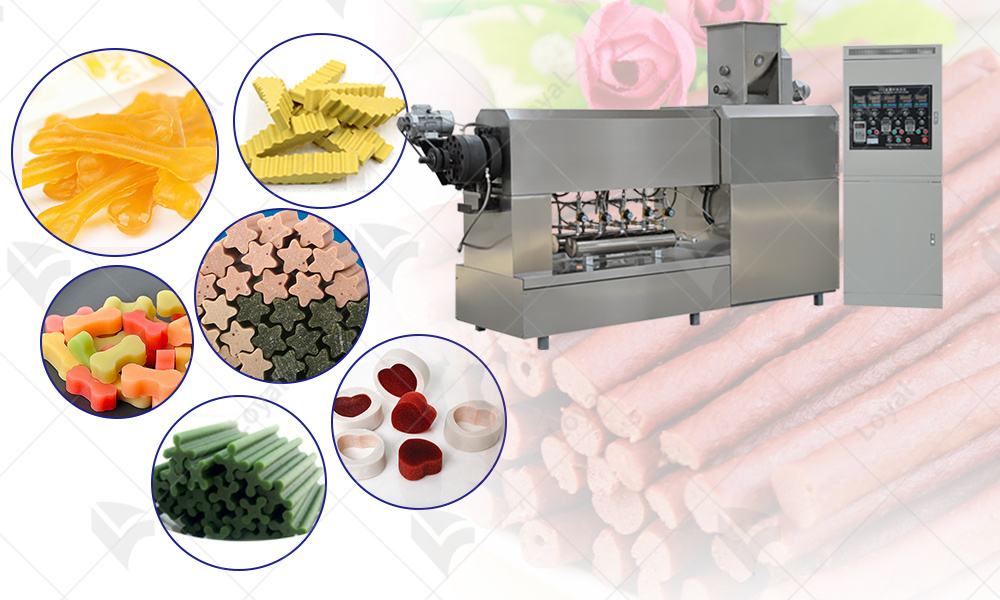

May 25, 2023Introduction Of Pet Chewing food process line:

Dog chew food is a kind of pet food, because dogs have a hobby of chewing bones, the shape of dog chews are designed to suit the characteristics of dog play. The shape of the gum is like bones, balls, circles, sticks, shoes and particles, etc. The main ingredients of dog gum are made of meat cowhide, meat pig skin, wood shavings, and other dog food through special processing, which can be used for dogs to eat a high-protein meat nutritional goodies, which is non-toxic and harmless to dogs.

1.Dog chew gum is specially designed for dogs to clean the cavity of the chew. In the puppy teething stage dental bed is very itchy, with dog chew gum not only to relieve the pain of the dog, but also to protect the items at home from being damaged. The dog chew gum is different from other foods, when the dog chews the dog chew gum, stimulate saliva to produce in the tooth bacterium acid, the dog in the process of chewing, chewing to regulate appetite, healthy teeth, pre

The effect of preventing bad breath.

2.Dog chew gum also has its other major feature, it as an edible toy, can help pets in the owner has no time to care about it, can pass the time of boredom, to avoid dogs everywhere tearing things at home, can avoid the dog demolition home.

The Production Line Details :

| Capacity | 80-100KG/h |

| Electricity supply | Customized according to your local electricity situation. |

| Machine details | 1. Stainless steel,:201, 304, 316, on request.

2. Electrical components can be ABB, Delta, Fuji, Siemens; famous brands. |

| Certificates | CE,GOST,TUV,BV |

| Raw material | Meat meal; bone meal; flour and other chemical additives |

| Product colour | Brown, yellow,Pink, yellow, green and other colors |

Flow Chart of crisp chips production line:

- Mixer----2. Screw conveyor----3. Twin screw extruder----4. Cooling machine----5.Cutter----6. Hoister----7. Multi-layer Oven

Flow Chart Diagram:

Feature Of Pet chewing food production line:

1.High degree of automation: Ithas a very high degree of automation, which can well meet the needs of customers and fully meet the needs of various enterprises.

2.Large output: It can realize multiple batch processing, thus avoiding problems such as equipment downtime and long downtime due to different batches. The output of the equipment is large, thus ensuring the production efficiency and quality. At the same time, the production speed of the equipment is fast, and the output can be adjusted at any time according to the output needs of different users.

3.Low energy consumption: It can effectively reduce the utilization rate of energy and achieve the purpose of saving costs.

4.Sanitation and cleaning: The equipment adopts a new type of dust removal equipment, which can well avoid dust pollution to the surrounding environment and ensure environmental hygiene. In the process of processing,a certain amount of dust will be generated. If the dust is not effectively removed, the dust will cause harm to the health of the workers.

5.Easy to operate: The device is easy to operate and easy to use, whether it is a small-scale enterprise or a large-scale enterprise, it can be easily used.

The above are the characteristics of the bread crumb production line. This equipment has the advantages of large output, high efficiency and low energy consumption, and can meet the needs of various customers.

Feature Of Pet chewing food production line:

1.Mixer:Mixer makes the raw material adding to water and other chemical additive fully mixed.The mixing process ensures that the ingredients are evenly distributed and forms a dough that is pliable and easy to work with.

2.Screw Conveyor:Screw conveyor can not only convey on the level but also by any angel these materials can be conveyed in the stainless steel roller without leaking, dust pollution; meanwhile it can send the self-mixer to the feeding machine or the conditioner and directly send the discharge hole of the inflating extruder.

3.Twin screw extruder: The material is cooked and expanded in the high temperature and pressure environment of the extruder. The control system of the extruder, the feeding system and the rotary cutting system are all frequency-controlled, which has the advantage of being more energy-efficient and of making the material more homogeneous. The feed system is located next to the screw conveyor and the feed opening is also equipped with a stirring shaft, so that the material enters the extruder more evenly. After the extrusion, the material is puffed and formed into different moulds by different dies.

4.Cooling machine: By means of the cooler, the material can be chilled down quickly to facilitate the next step in the process.

5.Cutter: The cutting machine can form different shapes that we want and can make the material more beautiful.

6.Hoister: Transport of materials to the flavouring drums

7.Multi-layer ovens: Ovens you can choose different ovens according to your production needs, for large production choose a seven layer oven, for small production choose a three layer oven. In addition, our ovens can choose electric heating, gas heating and gas heating, etc. Electric heating is the most expensive, oil and gas prices are the same, but their burners are not the same. Drying through the oven, so that the drying effect can be better and save time, and can extend the preservation time of the material.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan