Home > Food Processing > Professional Corn Curls Making Machine With Custom-Design Service

Professional Corn Curls Making Machine With Custom-Design Service

May 17, 2023Introduction of Corn Curls Making Machine:

Corn curls are a common food in life, not only as a main meal to eat, but also as a snack to eat, thick rice fragrance corn curls is a childhood memory. Kurkure corn curls production line is the use of corn dregs (corn lush) as raw materials, extruded by the host to make irregular puffed food, after seasoning can be made into different taste of crispy products, loved by consumers. The extruder feeds the hopper with vibration and can adjust the size of raw material flow. Feeding screw speed is controlled by frequency conversion and can be adjusted arbitrarily. Mechanical gear linkage to achieve manual control of the extrusion head gap and hand wheel control of the machine seat linkage can make it easier for the feeding screw to enter the extrusion barrel.

The new corn curls production process has the advantages of short production process, time saving, lower production cost and less equipment investment. In addition, the product has the characteristics of stable quality and long shelf life.

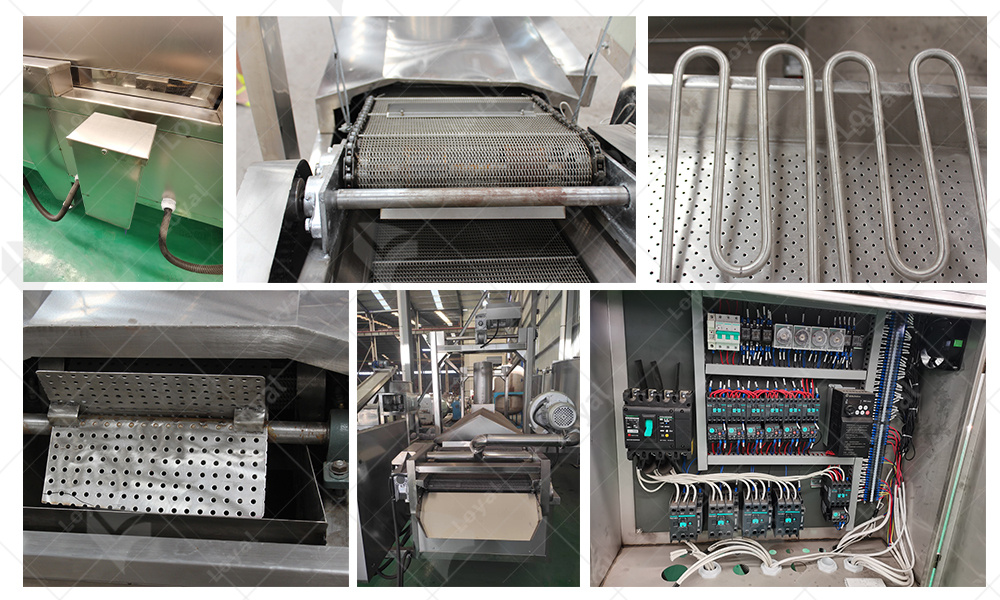

The whole corn curls production line can automatically complete the production from mixer, screw conveyor, rotary head extruder, hoister, separating drum, vibrate feeder, continuous fryer,vibrate de oil machine and flavoring line to the finished product.

Details of the production line:

| Production capacity | 125-230kg/h |

| Electricity supply | Customised according to your local electricity situation. |

| Machine details | 1.Stainless steel:201, 304, 316, on request.

2.Electrical components can be ABB, Delta, Fuji, Siemens, famous brands. |

| Certificates | CE,GOST,TUV,BV,SGS |

| Apllicatins | Kurkure/Cheetos/Niknak/ Corn Curls etc |

Flow chart of Corn Curls processing line:

Mixer-Screw Conveyor- Rotary Head Extruder- Hoister-Separating Drum-Vibrate Feeder-Continuous Fryer-Vibrate De Oil Machine-Flavoring Line.

Features of the Corn Curls processing line:

1.Productivity:automated system for controlled and stable production on a continuous basis, easy and quick product change, automatic start-up, simple cleaning and maintenance procedures.

2.Economical: low investment, quick results.

3.Environmental protection: moderate output and energy saving.

4.Intelligent control system: PLC control of production to ensure optimum process parameters for each recipe.

5.Automatic lubrication system can reduce power consumption and prolong service life.

Parameters of the Corn Curls Production Line:

|

Model |

Installed Power

(KW) |

Power Consumption

(kw) |

Capacity

(kg/h) |

Dimension

(m) |

| LY1 Corn Curls Production Line | 134 | 94 | 125-140 | 17000*1100*2500mm

|

| LY2 Corn Curls Production Line | 136 | 95 | 200-230 | 17300*1200*2600mm

|

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan