Home > Food Processing > What Biscuit Line Including?

What Biscuit Line Including?

February 16, 2023Introduction of Automatic biscuit production line:

The main raw materials of biscuits are wheat flour, and then add sugar, fat, eggs, dairy and other auxiliary materials. Depending on the formula and production process, men biscuits can be divided into two categories: tough biscuits and crispy biscuits. The characteristics of tough biscuits are that the shape of the printing is mostly concave, and the surface is acupuncture. The surface of the product is smooth and smooth, and the cross -section structure is layered. It has a crispy feeling, chewing, and crispy features when chewing.

Biscuit production line is the advance design for production the kinds of hard and soft biscuits ,with sandwich biscuit.The biscuit plant equipment can be combined and displayed according to the customer's factory space or biscuit technical.

The Details of Biscuit Production Line :

| Capacity | 50kg-1000kg |

| Power Supply | Based on 380V 50 Hz 3 phase. Customized according to your local power. |

| Machine details | 1.Stainless steel,:201, 304, 316, on request 2. Electric parts can be ABB, Delta, Fuji, Siemens; Famous brand as your demand. |

| Certificate | CE,GOST,TUV,BV |

| Raw Material | Wheat flour, corn, rice, oat, etc. |

| Products Color | White, Yellow |

| Products type | Soft biscuit, hard biscuit, sandwiching biscuit. |

The Flow Chart of Biscuit production line :

Small biscuit production line: Flour Mixer- Shaping&Cutting- Controller- Baking Oven- Spraying Oil-Cooling- Packing

Large biscuit production line: Agitation of wheat flour eges, granulated sugar and condiments--Dough Mixing--Biscuit forming (roll printing, roll cutting)--oven Baking--Oil Spraying--conveys cooling--Sorting-sandwiching--packaging.

The Detailed introduction of Biscuit Production Line :

Put the raw materials into the Dough maker, and then press it into a dough by Gauge Roll. Then, the biscuits are printed through the mold of the Rotary Cutter or Reciprocating Cutter. The side scrap are recovered through the Rest Conveyor and the Side Scrap Return System, then biscuits are sent to the Oven, after being cooked, it is transported to the Biscuits rotating machine by Peeling machine. Finally, it is sprayed on the biscuit surface by the Oil Spray Machine, and then cooled. After that, it is organized by the Biscuit Stacking Machine. Finally, it is sent to the packaging machine.

The equipment using and advantages of Biscuit production line :

Dough maker: Mix flour with water or other things, you can use it alone or with other machines.Full stainless steel, not easy to rust.

The mixing teeth are thickened, it is not easy to deform and easy to clean, and the integrated molding (no welding seam, no material, easy to clean) multifunctional, suitable for the stirring of crispy and tough raw materials.

Rotary Cutter or Reciprocating Cutter: Put the mixed dough in this machine, and then form a biscuits of various shapes before baking.

The exclusive design of the pressure roller, from the feed to the outbound end, the diameter of the pressure roller is from large to small, and the pressed facial pieces are easy to form. The dough is from thick to thin, uniform thickness, not easy to break, the finished product is good, does not deform, pressure roller, pressure roller, pressure roller, pressure roller For alloy pressure rollers, the hardness is extremely high

Rest Conveyor:Separate the side scrap from the biscuits.

Side Scrap Return System: return the side scrap.

Oven: Cook the biscuits.

Biscuits rotating machine: Save space

Oil Spray Machine: Spray fuel on the surface of the biscuits to make the taste better.

Biscuit Stacking Machine: Stack the biscuits to make the packing easier.

Packaging machine: Pack biscuit and beautify the product etc.

The Flow Chart Diagram of Biscuit Production Line :

Our engineer could design the layout drawing according to customer’s dimension of the factory for the bread crumbs machines

The Feature of Biscuit production line :

- Productive: Automated systems for controlled and consistent production on a continuous basis, easy and quick product changeover, automated start up, simple cleaning and maintenance procedures.

- Flexible Formula: Processing of a wide range of raw materials, such aswheat flouretc;

- WidelyApplication: Easy adaptation to extend the range of products by changing the segments screw;

- Smart Control System: PLC Control of production to ensure optimized process parameters for each recipe;

- Advanced Die and Cutting system: This designs give processors an entirely new set of templates to create innovative shapesof biscuits.

- Automatic lubrication systemcan lower down power consumption and prolong the life.

The Line Parameter of Biscuit Production :

| Model | Capacity

(kg/h) |

Finished Biscuit |

| LY-325 processing line | 50-60kg/h | Soft biscuit, hard biscuit, sandwiching biscuit |

| LY-380 processing line | 100kg/h | Soft biscuit, hard biscuit, sandwiching biscuit |

| LY-400 processing line | 150-200kg/h | Soft biscuit, hard biscuit, sandwiching biscuit |

| LY-600 processing line | 400-500kg/h | Soft biscuit, hard biscuit, sandwiching biscuit |

| LY-800 processing line | 600-800kg/h | Soft biscuit, hard biscuit, sandwiching biscuit |

| LY-1000 processing line | 1000kg/h | Soft biscuit, hard biscuit, sandwiching biscuit |

The Applications of Biscuit production line :

Hard,soft biscuit production line, with a variety of different molds, different formulas, can produce a variety of different specifications of hard,soft biscuits.

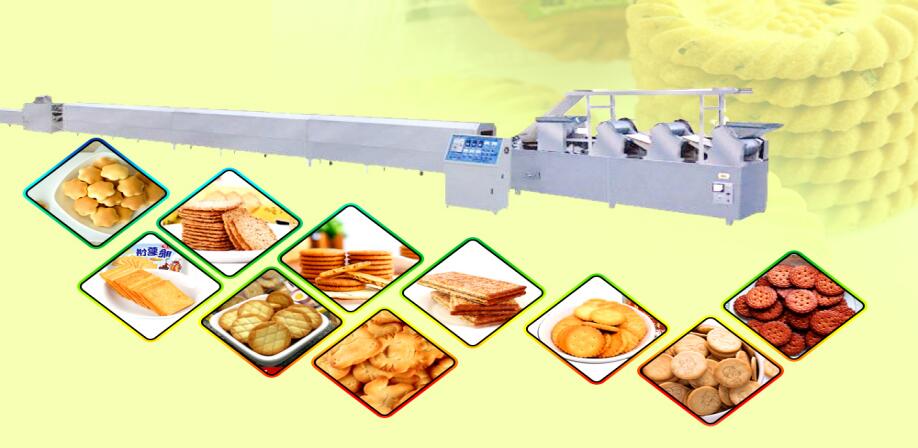

The Machine photos of Biscuit production line :

Machines Materials: All the machines are made by stainless steel.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan