Home > Food Processing > What Is Macaroni Line Technology?

What Is Macaroni Line Technology?

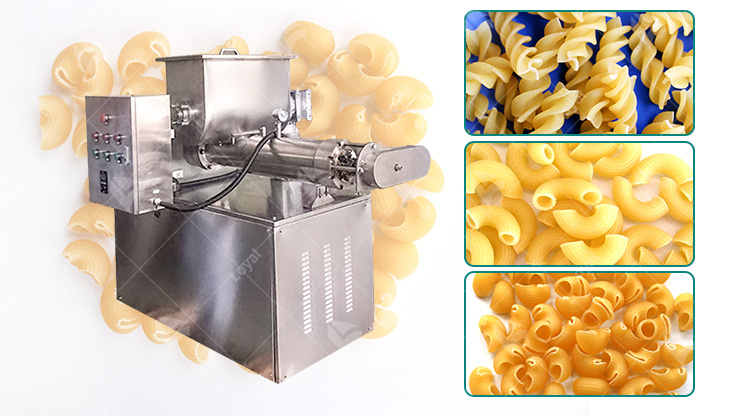

May 16, 2023Introduction Of Macaroni Making Machine:

A macaroni making machine is a device used for producing macaroni, a type of pasta that is commonly consumed worldwide. It is an automated machine that helps to streamline the production process of macaroni. The machine has a series of components that work together to mix, knead, and shape the dough into macaroni shapes.Macaroni making machines are commonly used by large-scale pasta manufacturers, although smaller machines are also available for home use. These machines can produce a wide variety of macaroni shapes and sizes, and they can be customized to suit specific production needs. They are efficient and fast, allowing for high production rates and consistent quality. Overall, macaroni making machines are an essential tool for anyone looking to manufacture macaroni on a large scale.

Flow Chart Of Commercial Macaroni Processing Line:

1.Mixing→2.Extruding→3.Cutting→4.Drying→5.Cooling→6.Sorting→7.Packaging

The Equipment Using In The Macaroni Making Machine:

1.Mixer: Used to mix the durum wheat flour, water, and any other ingredients to form a dough.

2.Extruder: Used to shape the dough into various macaroni shapes such as spaghetti, fusilli, penne, and macaroni.

3.Cutter: Used to cut the extruded macaroni into the desired length.

4.Dryer: Used to dry the macaroni at a controlled temperature and humidity to remove excess moisture and ensure a long shelf life.

5.Cooler: Used to cool the dried macaroni to room temperature.

6.Sorting machine: Used to sort the macaroni according to size and shape.

7.Packaging machine: Used to package the macaroni into

Feature Of Automatically Macaroni Machines:

1.Automated Production: The machines' automated nature ensures that the production process is smooth and consistent.

2.Production Capacity: Macaroni making machines are designed with high production capacities and can produce large quantities of macaroni in a short period.

3.Durability: Macaroni making machines are built to last, with sturdy frames and components. They are made from high-quality materials, such as stainless steel, which can withstand the harsh production environment.

4.Energy Efficiency: Macaroni making machines are designed to use minimal energy while operating efficiently.

Parameter Of Macaroni Machine:

| ITEM NO | Power

(kw) |

Capacity

(kg/h) |

Dimension

(mm) |

| LYS-100 | 12 | 100kg/h | 1200*800*1500 |

| LYS-200 | 22 | 200kg/h | 1500*1000*1800 |

| LYS-300 | 30 | 300kg/h | 2300*3000*4200 |

| LYS-500 | 37 | 500kg/h | 2700*3000*4200 |

| LYS-1000 | 75 | 1000kg/h | 4000*3500*5200 |

Applications Of Automatic Macaroni Production Line:

| 1 | Large Scale Pasta Production | The automatic macaroni production line is capable of producing large quantities of macaroni in a short period. |

| 2 | Mass Catering | The machine can automatically produce different shapes and sizes of macaroni making it ideal for mass catering, such as restaurants, hotels, and canteens. |

| 3 | Export | The automatic macaroni production line is popular among pasta manufacturers for export purposes. |

| 4 | Customized Production | The machine is customizable, which allows manufacturers to produce macaroni in different shapes, sizes, and colors. |

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan