Home > Production Lines > Bread Crumbs Production Line > Professional Bread Crumbs Making Machine With Custom-Design Service 50hz 3 Phase

Professional Bread Crumbs Making Machine With Custom-Design Service 50hz 3 Phase

-

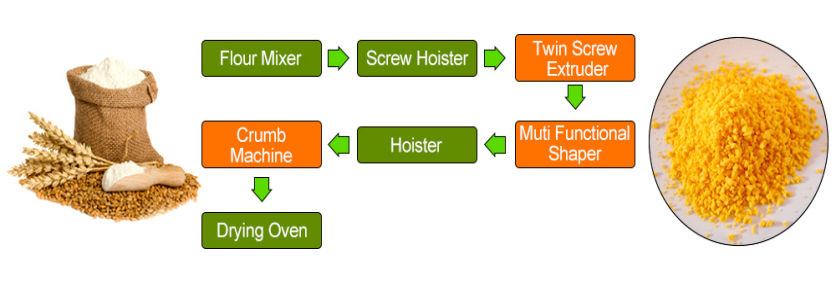

As a professional bread crumbs making machine manufacturer, our automatic breadcrumbs processing line design good manufacturing process. Bread crumbs making machinery can take wheat flour, corn, rice, oat, and others as raw materials, to make the crispy various bread crumbs for sales.

- LOYAL

- PBPL-2019

- Shandong China

- 1 sets/Bread Crumbs Production Line

- T/T,L/C,D/P

- 20 days /Bread Crumbs Production Line

- Wooden case or wooden pellets depended on clients' require

| Brand Name: | LOYAL | Model Number: | PBPL-2019 | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 sets/Bread Crumbs Production Line | Payment Terms: | T/T,L/C,D/P | Supply Ability: | 20 days /Bread Crumbs Production Line |

| Packaging Details: | Wooden case or wooden pellets depended on clients' require |

Professional bread crumbs making machine is specially designed and developed according to market demand. The whole bread crumbs production line can be finished from the raw materials, extrusion, drying to finished products automatically. The bread crumbs produced by the twin-screw extruder change the traditional production process of bread crumbs.

The bread crumbs production line is a set of fully automatic production line, from raw material mixing, conveying, extrusion and curing, forming, drying, and fully automatic assembly line production. The bread crumbs processing line can be used with a wide range of raw materials, including flour, rice flour, corn flour, corn starch, soybean flour, etc. The bread crumbs making machine can produce bread crumbs of various shapes, including needle, granular, snowflake, flake, and star shape or multiple shapes.

WHAT IS THE DIFFERENCE BETWEEN THE EXTRUDED BREAD CRUMB PROCESSING LINE AND THE TRADITIONAL BREAD CRUMB MANUFACTURING PROCESS?

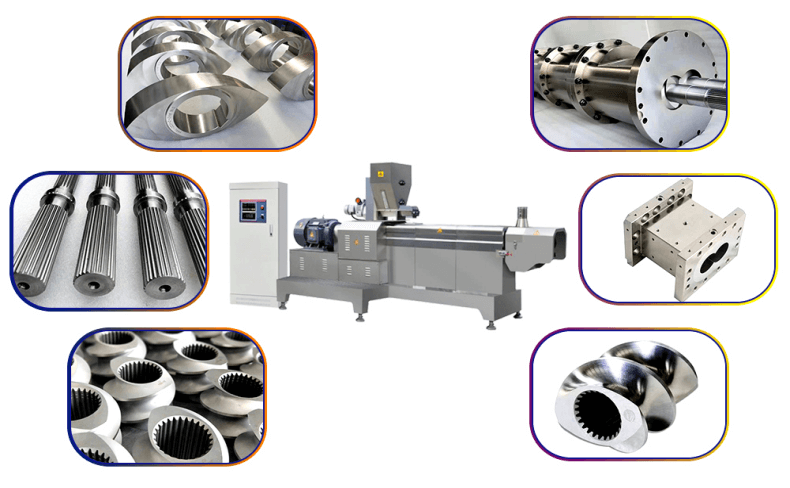

The main equipment of the professional bread crumbs making machine, the twin-screw extruder can complete the traditional electrode bread crumbs raw material mixing, dough mixing, grouping, machine (pressing machine), fermentation, maturation and other production processes. It is high temperature, high pressure, short Time and low moisture hot extrusion process.

The advantages of extruded bread crumbs grinder machine:

| 1. | Fewer production personnel, short production process, high unit output, energy saving and high efficiency, and reduced production costs. |

| 2. | Simple equipment, small footprint, and convenient operation. |

| 3. | Wide use of raw materials, easy to change product varieties and shapes, products are more diverse. |

EXPANDED CRUMBS VS.TRADITIONAL BREADING CRUMB

| Expanded Crumbs | Traditional Breading Products |

| Reduce equipment, labor and energy costs | Cost is high |

| Space is small | Big space |

| Relies on protein development and the expansion of starch fraction in the cereal grain instead of fermentation | Yield fine particle size or granulation when ground |

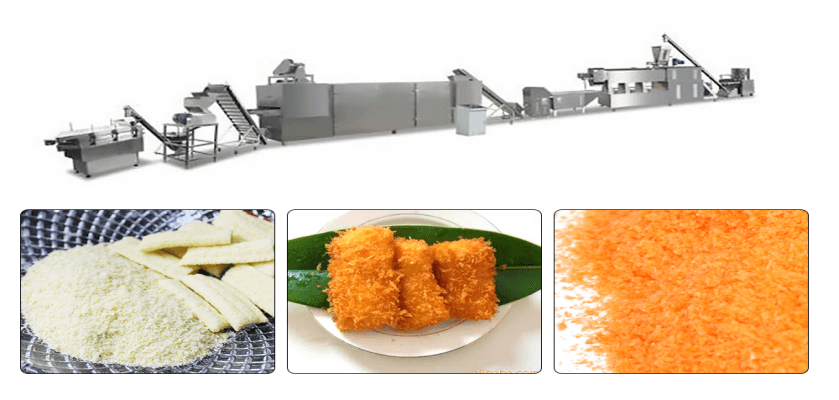

Bread crumb is the wide spread use food increase supplementary material, mainly uses in the western-style food exploding the beefsteak, exploding the chicken leg and so on to fry in oil the supplementary material. After frying, the crumbs become straight up bit by bit. They are not only puffed and nice in appearance but also crisp and delicate in taste.

THE PRODUCTION LINE DETAILS OF BREAD CRUMBS MAKING MACHINE

| Capacity | 120kg-1000kg |

| Power Supply | Based on 380V 50 Hz 3 phase. Customized according to your local power. |

| Machine details | 1.Stainless steel,:201, 304, 316, on request 2. Electric parts can be ABB, Delta, Fuji, Siemens; Famous brand as your demand. |

| Certificate | CE,GOST,TUV,BV |

| Raw Material | Wheat flour, corn, rice, oat, etc. |

| Products Color | White, Yellow |

| Products type | Particle, needle, rings, pillows shape, triangles, curls shape, etc. |

FLOW CHART OF COMMERCIAL BREAD CRUMBS PROCESSING LINE Flour Mixer--- Screw Hoister---Twin Screw Extruder--- Cutter --- Hoister--- Crumb Machine--- Drying Oven

FLOW CHART DIAGRAM OF BREAD CRUMBS GRINDER MACHINE DESIGN Our engineer could design the layout drawing according to customer’s dimension of the factory for the bread crumbs machines.

THE MAIN EQUIPMENT USING IN THE BREAD CRUMB MAKING MACHINE

| Machines | Function |

| Mixer | Mixing the raw materials |

| Screw conveyor | Conveying the raw material into the extruder |

| Twin-screw extruder | Extruding & puffing |

| Cutter | Cut off food for easy delivery |

| Hoister | Conveying semi-finished products into crumbing machine |

| Dryer | Dry the products |

PARAMETER OF BREAD CRUMB MAKING MACHINERY PROCESSING LINE

| Model | Installed Power(KW) | Power Consumption(kw) | Capacity(kg/h) | Dimension(m) |

| LY65 | 74 | 53 | 120-150 | 17*1.2*2.2 |

| LY70 | 95 | 76 | 200-240 | 20*1.5*2.2 |

| LY85 | 139 | 117 | 400-500 | 28*3.5*4.3 |

APPLICATIONS OF AUTOMATIC BREAD CRUMB PRODUCTION LINE FOR SALE Bread crumbs is a widely used food additive for deep fried food, and mainly for frying food surface. Such as: Fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious and nutritious.

| NO. | Classification Of Breadcrumbs |

| 1 | Chips, sticks shape bread crumbs |

| 2 | Sizes-balls shape bread crumbs |

| 3 | Needle bread crumbs |

| 4 | Triangles, curls shape bread crumbs |

| 5 | Letters shape bread crumbs |

| 6 | Animals, stars shape bread crumbs |

LOYAL MACHINE MAIN PHOTOS OF BREADCRUMB PRODUCTION LINE Machines Materials: All the machines are made by stainless steel.

FEATURE OF AUTOMATICALLY BREAD CRUMBS MACHINES

| Item No. | Features | Detail descriptions |

| 1 | Productive | Automated systems for controlled and consistent production on a continuous basis, easy and quick product changeover, automated start up, simple cleaning and maintenance procedures. |

| 2 | Flexible Formula | Processing of a wide range of raw materials, such as corn, wheat, rice, potato, oat etc. |

| 3 | Widely Application | Easy adaptation to extend the range of products by changing the segments screw. |

| 4 | Smart Control System | PLC Control of production to ensure optimized process parameters for each recipe. |

| 5 | Advanced Die and Cutting system | This designs give processors an entirely new set of templates to create innovative shapes and sizes-Balls, animals, stars, rings, pillows, triangles, curls, chips, sticks, and also letters. Automatic lubrication system can lower down power consumption and prolong the life. |

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Fully automatic bread crumb production line

Fully automatic bread crumb production line