Home > Production Lines > Introduction to macaroni and cheese

Introduction to macaroni and cheese

-

Rigatoni, which belongs to the category of pasta. The earliest pasta-based food in Europe was brought back to Italy from China by the traveller Marco Polo in 1295. Some historians believe that noodles were introduced to Europe by Asian slaves who worked as cooks in the homes of wealthy Italians. In the 18th […]

- Donghe

- JinanShandong

- 1 set

- Wrapped in plastic film before being loaded into containers

- Qingdao Chian

| Brand Name: | Donghe | Place of Origin: | JinanShandong | Min.Order Quantity: | 1 set |

| Packaging Details: | Wrapped in plastic film before being loaded into containers | Port: | Qingdao Chian |

Rigatoni, which belongs to the category of pasta. The earliest pasta-based food in Europe was brought back to Italy from China by the traveller Marco Polo in 1295. Some historians believe that noodles were introduced to Europe by Asian slaves who worked as cooks in the homes of wealthy Italians.

In the 18th century, the owner of a shop near the city of Naples that dealt in noodles and pasta was called Macca Roni. One day, while playing, Ronnie's young daughter rolled the noodles into hollow strips and hung them on a clothesline. Ronnie cooked the hollow noodles and mixed them with tomato sauce, which became a big hit with customers. Ronnie then built the world's first macaroni factory and named it after himself. The pasta gradually spread to Europe and many parts of the world.

Q&A

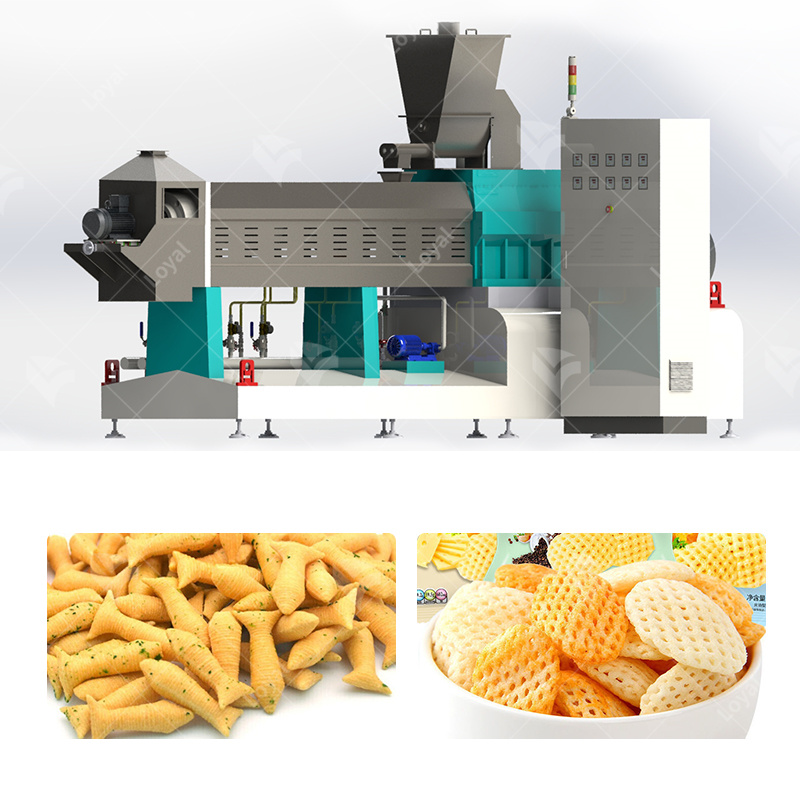

- The production process of our pasta and macaroni equipment is based on the traditional European production process, not just on the extruder, and is truly detailed, with each process being in line with the European pasta production process. We have systematically adopted the key processes of vacuum mixing, temperature-controlled extrusion, continuous pre-drying, convection drying and moisturising and cooling to achieve continuous, industrialised production.

- The production equipment we offer is an industrial, continuous production package that eliminates the need to rely on a large number of skilled manual operators, thus allowing for standardised production.

- We are a production company integrating R&D, production, sales and after-sales service, located in Changqing District, Jinan. Here we can demonstrate the production process on site to give you a more intuitive feeling.

Flow Chart Diagram:

Feature Of Macaroni process line:

- High degree of automation: Ithas a very high degree of automation, which can well meet the needs of customers and fully meet the needs of various enterprises.

- Large output: It can realize multiple batch processing, thus avoiding problems such as equipment downtime and long downtime due to different batches. The output of the equipment is large, thus ensuring the production efficiency and quality. At the same time, the production speed of the equipment is fast, and the output can be adjusted at any time according to the output needs of different users.

- Low energy consumption: It can effectively reduce the utilization rate of energy and achieve the purpose of saving costs.

- Sanitation and cleaning: The equipment adopts a new type of dust removal equipment, which can well avoid dust pollution to the surrounding environment and ensure environmental hygiene. In the process of processing,a certain amount of dust will be generated. If the dust is not effectively removed, the dust will cause harm to the health of the workers.

- Easy to operate: The device is easy to operate and easy to use, whether it is a small-scale enterprise or a large-scale enterprise, it can be easily used.

The above are the characteristics of the macaroni production line. This equipment has the advantages of large output, high efficiency and low energy consumption, and can meet the needs of various customers.

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Industrial microwave drying equipment

Industrial microwave drying equipment Fully automatic bread crumb production line

Fully automatic bread crumb production line About the puffed food machine

About the puffed food machine Fully automatic stainless steel instant noodle production line

Fully automatic stainless steel instant noodle production line