Home > Production Lines > Snack Food Extruder Machine > Automatic Twin Screw Extruder Machine Production Line

Automatic Twin Screw Extruder Machine Production Line

-

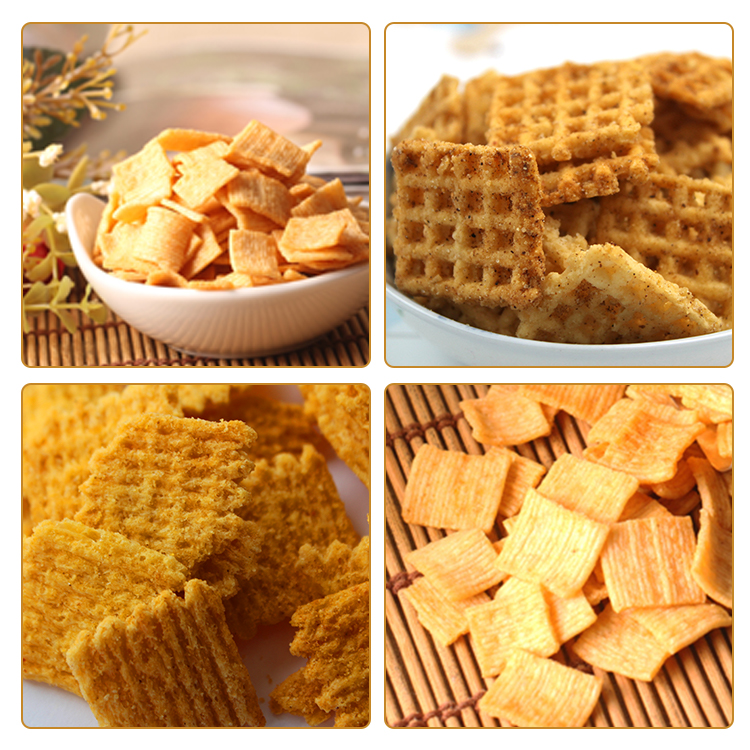

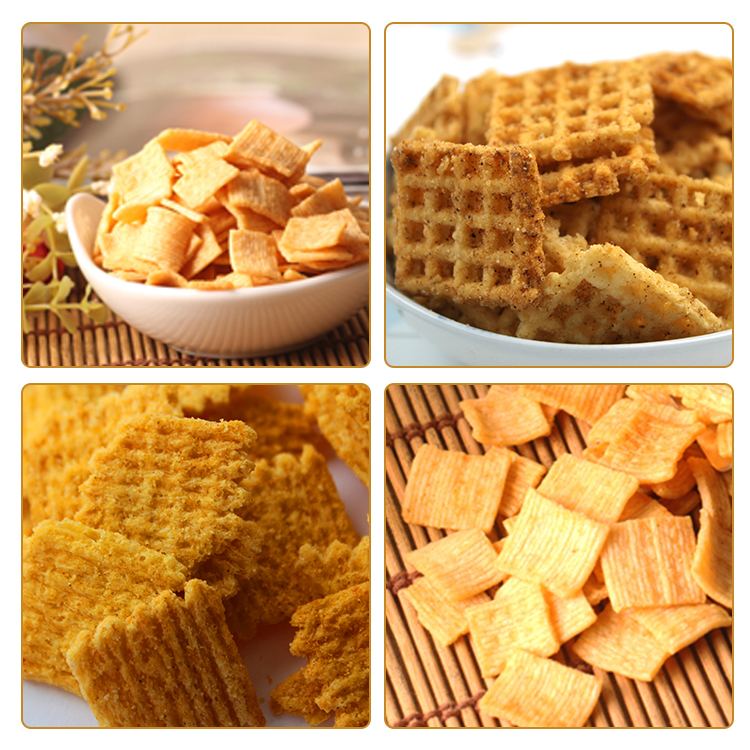

As a professional Twin Screw Extruder Machine manufacturer, we have been in this field for 15 years. Our Screw Extruder Machine design good manufacturing process. Twin Screw Extruder Machine can take Corn, potato grains and others as raw materials, to make the Bread Crumbs, corn puff, Corn Snack, Puffed Rice for sale.

- LOYAL

- PCPL-1

- Shandong China

- 1 sets/Automatic Twin Screw Extruder Machine Production Line

- T/T,L/C,D/P

- 20 days /Automatic Twin Screw Extruder Machine Production Line

- Wooden case or wooden pellets depended on clients' require

| Brand Name: | LOYAL | Model Number: | PCPL-1 | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 sets/Automatic Twin Screw Extruder Machine Production Line | Payment Terms: | T/T,L/C,D/P | Supply Ability: | 20 days /Automatic Twin Screw Extruder Machine Production Line |

| Delivery Detail: | Wooden case or wooden pellets depended on clients' require | Voltage: | 380V | Warranty: | 1 YEAR |

| Raw material: | Fresh potato,cassava | Capacity: | 100-1000kg/h |

Twin Screw Extruder process developed by twin screw extruder manufacturers more then 30 years, enables the continuous production of highly homogeneous and finely structured products, using bio-sourced or synthetic raw materials. It is used to produce a wide range of Food & Feed products, our multifunctional food extruder machine offer flexible, reliable processing for your breakfast cereals, food ingredients, pet food and aqua feed products.

Product parameters of Twin Screw Extruder Machine:

| Applicable Industries: Twin-screw extrusion processing versus conventional food processing |

| Converter: Customizable |

| Capacity: 100-150g/h 200-250kg/h 300-500kg/h 300-500kg/h |

| Certification: CE,ISO9001 |

| Model: LY65 LY70 LY85 LY75 LY95 |

| Voltage: customizable |

| Equipment Material: |

| 304 Stainless Steel |

| Service Long Service Life |

Product modle of Twin Screw Extruder Machine:

DIFFERENT MODEL OF ORDINARY TWIN SCREW EXTRUDER FOR SALE

| Model | Installed Power | Power | Output | Size(L×W× H) |

| LYP65 | 47kw | 30KW | 180kg/h | 3500x950x1850mm |

| LYP70 | 53kw | 37KW | 200-250kg/h | 3200x760x2000mm |

| LY70L | 53kw | 37KW | 200-250kg/h | 3200*930*2000mm |

| LYP85 | 144kw | 75KW | 500kg/h | 1100*2350mm |

MULTIFUNCTIONAL STANDARD SCREW EXTRUDER MACHINE FOR SALE

| LY75 | 98KW | 75kw | 200-500kg/h | 5200*1100*2800mm |

| LY95 | 142kw | 110KW | 600-1200kg/h | 6400*3000*3000 |

The application of a twin screw extruder.

As a twin Screw extruder machine manufacturer, Due to a wide range of extruder screws and barrels design, a double screw extruder technology is able to ensure food extruder machine manufacturing process to produce a wide range of Food & Feed products, making puffs snacks, pet food, fish feed, corn flakes, breakfast cereals, TVP, artificial rice, Bread Crumbs, corn puff. Many factories need this machine: Food manufacturing process plant, snack processing plant, Corn Snack Extruder, Puffed Rice/Corn Machine, Food & Beverage Factory, Food & Beverage Shop.

FUNCTION of Automatic twin Screw Extruder Machine Line

Extruding the mixture into different shapes(this machine uses different die can produce different shap

The main extruder adopts frequency speed controlling with high automation and stable per-formation.

The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer. Adopting the building block structure and combining willingly according to the different demand.

The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer. Adopting the building block structure and combining willingly according to the different demand.

Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

Self-cleaning, when stopping, it can be cleaned without disassembling.

According to different screw design rate to full different technology request.

This equipment has the wide material, multi-shape products and flexible collections.

The Features of a twin screw extruder.

Twin screw extruders consist of two intermeshing, co-rotating screws mounted on splined shafts in barrel. Due to a wide range of screw and barrel designs, various screw profiles and process functions can be set up according to process requirements. Hence, a double screw extruder technology is able to ensure transporting, compressing, mixing, cooking, shearing, heating, cooling, pumping, shaping, etc. with high level of flexibility. The major advantage of intermeshing co-rotating twin screw extruders is their remarkable mixing capability which confers exceptional characteristics to extruded products .

The difference between twin screw extruder and single screw extruder

SINGLE SCREW EXTRUDER VS TWIN SCREW EXTRUDER

1 .Capacity: Single screw is suitable for starch extrusion cooking but without puffing. The material stays in the food extruder machine for a long time; the twin-screw has good mixing and cooking ability, the material is short in the extruder, and is suitable for powder processing.

2 . processing capacity and energy consumption aspects: twin-screw extruder production, extrusion speed, unit output energy consumption is low, and single screw rod difference.

3 .Pellets become ready-to-eat snacks once they have been expanded in frying process or baking process.

4 .Snack pellets can be made with a wide variety of grains powder– corn starch, wheat starch, rice starch, tapioca starch– or potatoes starch and other vegetables powdder. They can also incorporate aromas and colors in their recipes.

5 .Operational aspects: Double screw manipulation easy, process control simple, Single screw operation is relatively complex, process control requirements are high.

Extruders has become the standard over time in several industries because it offers numerous advantages

--- More consistency in production and control of product quality

-- Increased productivity due to continuous processing, faster start up and shut down between product changes, quick changeover and advanced automation

--- Greater flexibility, with the capability to process a wide range of raw materials

--- Optimized footprint thanks to energy and water savings

--- Simple and easy to maintain and clean

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

CE ISO 100-400kg/h Dough Forming Single Screw Extruder Machine Green Food Equipment

CE ISO 100-400kg/h Dough Forming Single Screw Extruder Machine Green Food Equipment