Home > Production Lines > Snack Food Production Line > High Automatic Core Filling Snack Food Processing Line Self Cleaning, 220/380/415V

High Automatic Core Filling Snack Food Processing Line Self Cleaning, 220/380/415V

-

As a professional core filling snack food processing line supplier ,our core filling snack food processing line design good manufacturing process .core filling snack food processing line can take coco pops, cereal,oat, grains,potato flour and others as raw materials,to make the core filling snack rice crackers, core filling puffed snacks.

- LOYAL

- ABF-E ABF-G

- Shandong China

- 1 set/automatic fryer

- L/C,D/P,T/T

- 25 days /Snack Food Production Line

- Wooden case or wooden pellets depended on clients' requirement

| Brand Name: | LOYAL | Model Number: | ABF-E ABF-G | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 set/automatic fryer | Payment Terms: | L/C,D/P,T/T | Supply Ability: | 25 days /Snack Food Production Line |

| Packaging Details: | Wooden case or wooden pellets depended on clients' requirement |

Core filling snack food processing line takes grains flour or grain grits such as corn, rice, wheat, oat, rye, grains, potato flour. Etc as raw materials. It includes extrusion and expansion, sandwich, molding, cutting, spraying, seasoning to finished product production. Core filling snack food processing line is automatic. The finished corn flakes is very crispy and healthy for human. The core filling snack food processing line has many models, and the operation is simple, and the production of food is diverse. Choosing the appropriate configuration can produce sandwich cakes, sandwich tubes, puffed rice crackers, wheat chips snack, nutritious cereal breakfast, and other products.

| Capacity: | 120-150kg/h200-250kg/h300-500kg/h400-500kg/h800-1200kg/h |

| Equipment material: | Stainless steel/carbon steel |

| Hs code: | 84388000 |

| Key selling points: | Competitive price |

| Model: | Cfp65,cfp70,cfp85,cfp95 |

| Voltage: | 220/380/415v |

TECHNICAL MODLE OF CORE FILLING SNACK FOOD PROCESSING LINE

| Model | Installed power | Power consumption | Output | Size(l×w× h) |

| Cfp65 | 79kw | 55kw | 120-150kg/h | 19200x1200x2200mm |

| Cfp70 | 98kw | 69kw | 200-250kg/h | 21200x1500x2200mm |

| Cfp85 | 144kw | 101kw | 400-500kg/h | 26200x3500x4300mm |

| Cfp95 | 295kw | 222kw | 800-1200kg/h | 3100x3500x4300mm |

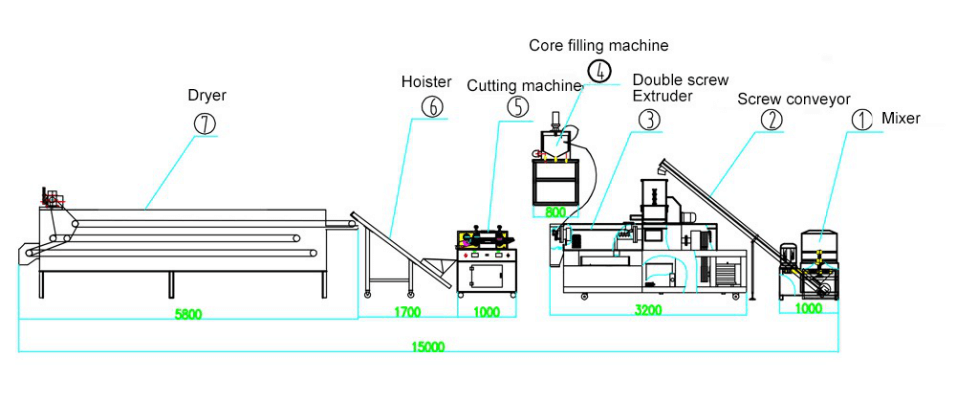

LOYAL CORE FILLING SNACK FOOD PROCESSING LINE PROCESSING DESIGN: Flour mixer-screw conveyor-double screw extruder -pulling&cutting machine - core filling machine-pvc hoister-dryer- single drum flavoring machine-packing machine

PROCESS DESCRIPTION OF CORE FILLING SNACK FOOD PROCESSING LINE:

| Item no. | Chocolate filled puff snack production line | Introduction of each part at chocolate filled puff snack production line |

| 1 | Flour mixer | Mixing the raw materials corn flour, rice flour, wheat flour,grain flour, additives, with a certain proportion of water uniform. |

| 2 | Screw conveyor | Delivering the mixed raw materials to the feeding hopper of the double screw extruder. The feeding of this equipment is convenient and fast, saving labor and high efficiency. |

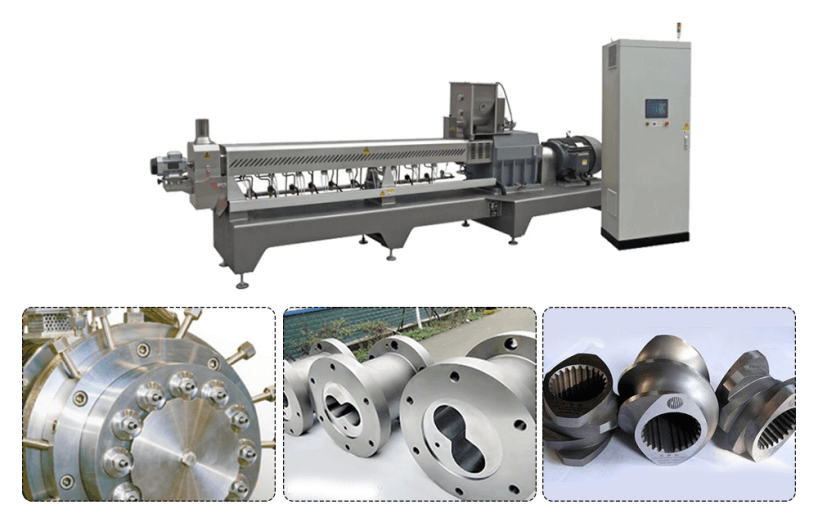

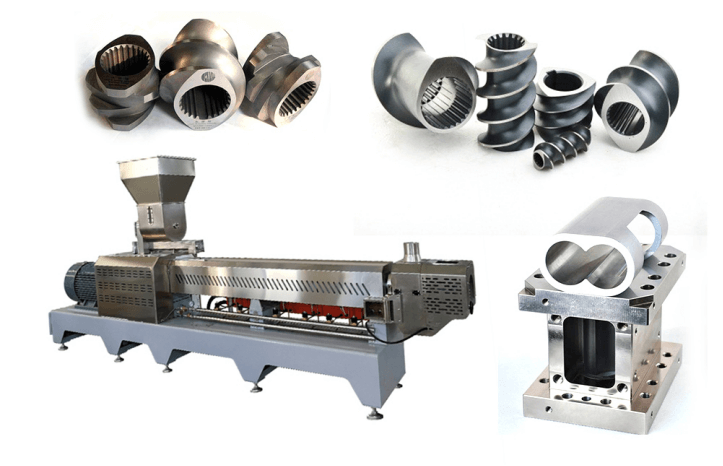

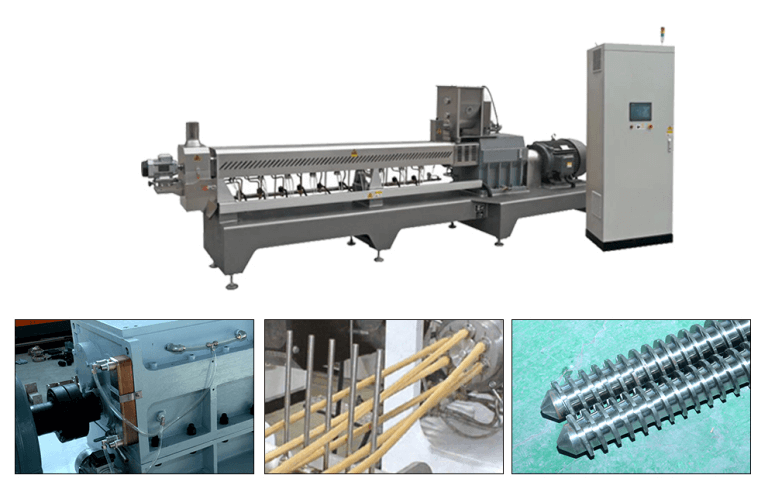

| 3 | Double screw Extruder | Extrude the mixed raw materials in a high temperature and high pressure environment and twin-screw extrusion, change the mold to obtain a specific particle size and shape |

| 4 | Pulling&cutting machine | Cutting the puffing snack in stick shape. |

| 5 | Core filling machine | Put the core inside the puffing snacks ,with heating function |

| 6 | Pvc hoister | Convey the produced feed particles to the multi-layer drying equipment. |

| 7 | Multi-layers oven | The oven is divided into electric oven, fuel oven, gas oven and steam oven. The temperature is adjusted between 0 and 150 degrees by the control cabinet. |

| 8 | Single drum flavoring machine | Flavoring the core filled snack with oil and flavoring.oil spraying and powder seasoning can be finished at one drums. Then ensure the material is seasoned evenly. |

| 9 | Packaging machine | Manual sealing machine and automatic packaging machine can be used, please call the manufacturer for details. |

APPLICATION OF CORE FILLING SNACK FOOD PROCESSING LINE

CORE FILLING SNACK FOOD PROCESSING LINE CUSTOMER FACTORY

DETAILS OF CORN FILLING SNACK FOOD PROCESSING LINE

THE FEATURE OD CORE FILLING SNACK FOOD PROCESSING LINE Slight weight, easy to use Compact structure, save space Easy operating, easy to learn Twin-screw High productivity, high efficiency Stainless steel, easy to learn

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

High Productivity Jam Center Snack Food Processing Line With Coating System

High Productivity Jam Center Snack Food Processing Line With Coating System 120kg-1200kg/h Corn Puff Making Machine/ Production Line

120kg-1200kg/h Corn Puff Making Machine/ Production Line