Home > Technical Blog > What Is the Advantages of Using Automatic Biscuit Production Lines?

What Is the Advantages of Using Automatic Biscuit Production Lines?

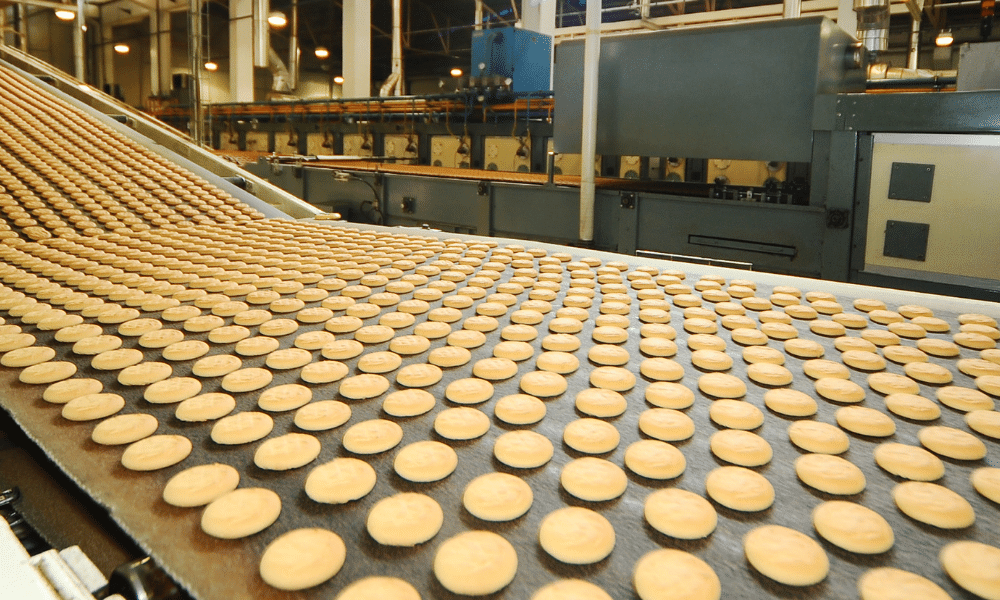

September 5, 2022In today's modern world, the demand for automatic biscuit production lines is on a rise. This is because it has numerous benefits over manual production. The most important benefit is that you can get high-quality biscuits in a short period of time. This means that if you are looking for a business that can give you a lot of profit, then this is one of the best options for you.

Another advantage of using an automatic biscuit production line is that it does not require any human labor to work with it. This means that if you are looking for a way to reduce your expenses, then this is one of the best options for you. Moreover, there are no chances of any mistakes made by human beings while working on an automatic biscuit production line.

In addition to these advantages, using an automatic biscuit production line also provides some other benefits as well .

Automatic Biscuit Production Lines have the advanced automatic control system, so that the whole production line has high automation, and it can save labor cost.

The automatic biscuit production line is mainly used to produce a variety of biscuits, cookies and cakes. The equipment is made up of mixing, extrusion, cutting and other parts. The indexing mechanism for the cutting part is driven by servo motors through the speed controller and the inverter. The temperature control system is based on temperature sensors placed at different positions in each part of the equipment. The mixer is equipped with a rotary valve to regulate the amount of water added during mixing to achieve an ideal dough consistency.

What Is the Advantages of Using Automatic Biscuit Production Lines?

High efficiency is one of the advantages of Automatic Biscuit Production Lines. When compared with traditional equipment, it can save time and increase production capacity.

The automatic biscuit production line has a series of functions, such as forming, baking and packaging. The whole process is completed automatically by the machine. The equipment can be used for making different types of biscuits, such as cookies, biscuits, crackers and breadsticks etc., according to different requirements of customers.

The biscuit production line consists of feeding system, forming system and baking system. In this way, it can complete the whole process of baking biscuits automatically without human intervention.

It has large output, so it is the best choice to use in large biscuit factory. In addition, the production line has less failure rate.

1.The automatic biscuit production line is composed by one set of batter mixing machine and one set of dough sheet cutting machine, which can produce up to 100 pieces of biscuits per minute. The biscuit making process includes: mixing dry ingredients with liquid ingredients, kneading dough, making biscuit strips, cutting strips into biscuits and baking biscuits. This kind of automatic biscuit production line has many advantages: high efficiency, low cost, simple operation and easy adjustments.

2.The automatic biscuit production line adopts electric control system to control every step of production process automatically, including materials feeding, mixing and forming dough; PLC controls all the working processes including temperature control and time control etc., which makes it easier for operators to operate this production line stably and efficiently

The biscuit produced by Automatic Biscuit Production Lines are good looking and of high quality, so it is loved by consumers.

The automatic production line is suitable for the production of various shapes of biscuits, such as round biscuits, heart-shaped biscuits and triangular biscuits. The equipment is made up of a series of production lines, including an automatic coating line, an automatic baking oven and an automatic cutting machine.

The automatic coating line can be divided into two types: spray coating or dipping coating. Spray coating is mainly used for chocolate coated biscuits and has the advantages of high efficiency and good appearance. The dipping coating adopts a water bath to coat chocolate on every biscuit. It has a high yield rate with beautiful appearance and good taste. In addition, there are also some other methods of coating such as roller coating, which is mainly used for sugar coated biscuits.

The automatic baking oven can be divided into two types: tunnel baking ovens or vertical baking ovens. Tunnel baking ovens are widely used in biscuit factories because they have high automation level, low energy consumption and small footprint area.

Another advantage of using the automatic biscuit production lines is that it has a high-performance grading function with its classifying screen, which can ensure the quality of the products.

Automatic Biscuit Production Line is a complete line for producing biscuits, which can produce high-quality biscuits. It is featured with a high production capacity, short production cycle and easy operation and maintenance. Automatic Biscuit Production Line consists of dough preparation section, extrusion section, breadcrumb coating section, conveying system and packing system etc.

The dough preparation section includes mixing device, dividing device, dosing device and pneumatic conveying system etc. It can prepare enough raw materials to meet the total needs of equipment. The extrusion section includes extruder machine and barrel with different specifications for different kinds of products, such as cookies and croutons etc. The breadcrumb coating section includes breadcrumb depositor device, depositing hopper and automatic rotation oven etc. The conveying system includes conveyor belt or chain conveyor etc., which transports biscuit pieces from raw material preparing section to packaging section automatically.

The automatic biscuit production line also has a highly functional wire cutting device that can cut out different types of designs on the biscuits.

This is the most unique feature of this type of biscuit production line. The wire cutting machine can cut out different shapes and designs on the biscuits. This makes it possible for you to produce a wide range of products with different shapes and sizes.

The automatic biscuit production line has many other features too. It can also automate other processes, such as filling, packaging and labelling.

You will find this type of biscuit production line in most large-scale bakeries and restaurants that offer a wide range of products to their customers.

Use the facility of automatic biscuit production lines to get wholesome biscuits with less human effort. The production line is more efficient and doesn't require much of the manual labor. This technology enables biscuits to be produced within very short time, thus reducing wastage. Moreover, this machinery does not allow much space requirement and are highly portable. With automatic biscuit production lines, you can make better quality biscuits at affordable prices with less effort.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan