Home > Food Processing > How To Make Wafer Biscuits By Loyal’s Wafer Biscuits Process Line

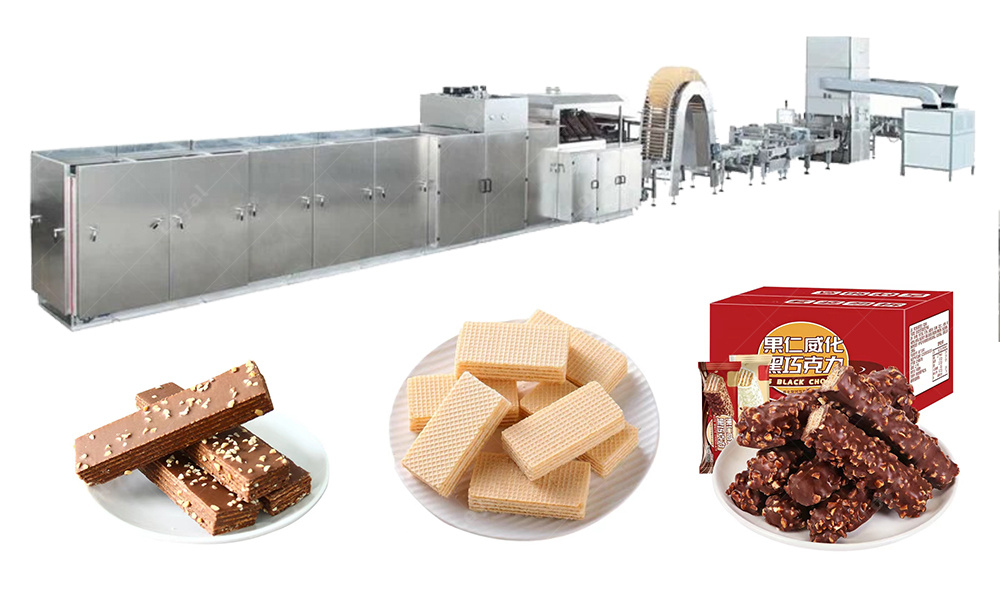

How To Make Wafer Biscuits By Loyal’s Wafer Biscuits Process Line

March 10, 20231.Description Of Loyal’s Wafer Biscuits Process Line

The wafer production line uses a door type sheet cooling machine, which has the characteristics of aesthetics, increased number of cooling sheets, convenient access for staff, and the addition of a vertical freezer and refrigeration system to better improve the temperature, humidity of wafer biscuits, improving quality and taste of wafer bisuits, kind of standard type of wafering equipment. This production line is suitable for small and medium-sized enterprises, independent vendors, and new developers who have certain requirements for production. Investors can also choose according to their own sales and production requirements.

2.Flow Chart Of Loyal’s Wafer Biscuits Process Line

Batter mixer--Baking oven--Wafer connecting machine--Wafer sheet cooler-- Wafer collecting machine--Cream spreading machine--Wafer cooling tower--Refrigeration system--Cutting conveyor--Wafer cutting machine

3.Details Of Loyal’s Wafer Biscuits Process Line

| Energy Consumption, Capacity And Length | |||||||

| Type / Plates | 27 | 33 | 39 | 45 | 51 | 63 | 75 |

| Electricity | 120kw | 140kw | 160kw | 180kw | 200kw | 240kw | 240kw |

| Daily Capacity (24hours) | 2-2.2 Tons | 3.0 Tons | 3.5 Tons | 4.0 Tons | 4.5 Tons | 5.2 Tons | 6.0 Tons |

| Total Length | 23.6m | 24.7m | 25.8m | 27.0m | 28.0m | 30.2m | 32.7m |

| Type / Plates | 27 | 33 | 39 | 45 | 51 | 63 | 75 |

| Gas | 13kg/h | 15kg/h | 19kg/h | 23kg/h | 27kg/h | 32kg/h | 37kg/h |

| Daily Capacity (24hours) | 2-2.2 Tons | 3.0 Tons | 3.5 Tons | 4.0 Tons | 4.5 Tons | 5.2 Tons | 6.0 Tons |

| Total Length | 23.6m | 24.7m | 25.8m | 27.0m | 28.0m | 30.2m | 32.7m |

4.Advantages Of Loyal’s Wafer Biscuits Process Line

| 1. Reliable performance, stable operation and long service life. All motors, electrical equipment, PLC, bearings are of international and Chinese famous brands |

| 2. The layout is reasonable, the structure is compact, the floor area is small, and the length of the oven is only 2/3 of that of similar products. |

| 3. High degree of automation, single machine can be controlled separately, simple operation and convenient maintenance |

| 4. The demoulding rate is high, and the yield is not less than 98% |

| 5. Special energy-saving design, low energy cost, reduce pollution to the extreme |

| 6. The machine material conforms to food hygiene standards, and all parts connected to food are made of stainless steel |

| 7. We have a variety of molds to produce different flower shapes. |

5.Application Of Loyal’s Wafer Biscuits Process Line

LOYAL’s wafer biscuits process line is the company digestion and absorption of Japanese technology, novel design, compact structure, high degree of automation equipment, from feed rolling, molding, waste recycling, drying, fuel injection, cooling automatic one-time completed, the company, to provide users with hundreds of mould and dozens of technological formula, by changing the mould and process recipe can produce market popular all kinds of high-grade cookies, such as butter cookies, biscuit, thin biscuit, soda biscuit, multi-dimensional animal crackers, cookies, vegetables, cookies, etc.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan