Home > Food Processing > Large Nutrition Powder Production Line

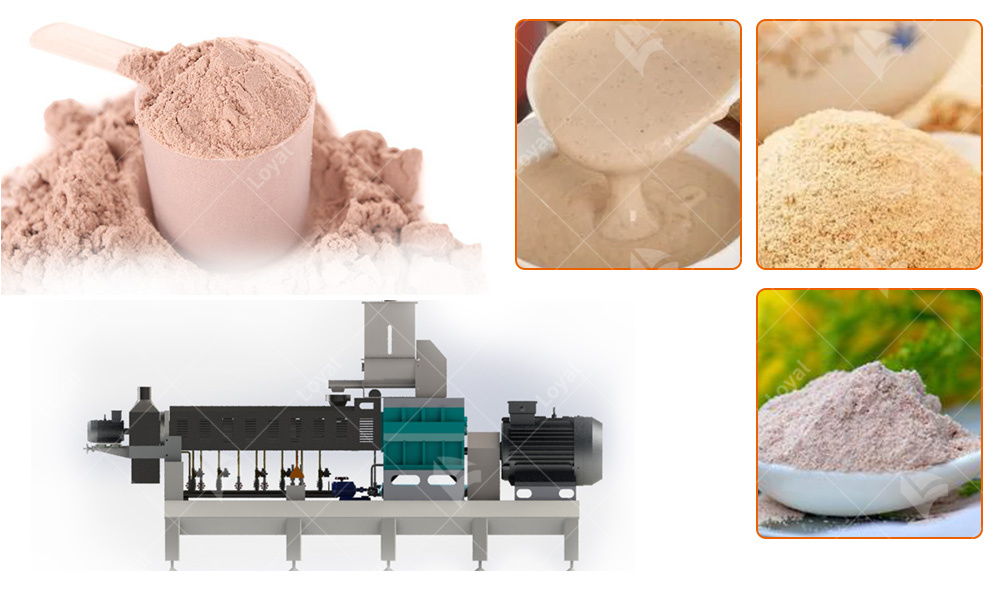

Large Nutrition Powder Production Line

March 9, 2023A large nutrition powder process line is a production line that is designed to produce a high volume of nutrition powder or food supplements. The size of a large nutrition powder process line can vary depending on the production capacity required, but typically includes a range of specialized equipment to handle the various stages of production.The specific equipment used in a nutrition powder process line can vary depending on the type of product being produced and the desired production capacity. However, common equipment includes blenders, extruders, ovens, and packaging machines.Overall, a large nutrition powder process line is a highly sophisticated system that requires specialized equipment and expertise to operate. The size and complexity of the system will depend on the production volume required, but all large nutrition powder process lines require careful attention to detail and quality control to produce high-quality, safe, and nutritious food supplements.

Large Nutrition Powder Process Line Flowchart

- Screw Conveyor--- 2. Ribbon Mixer --- 3. Screw Conveyor --- 4. Double Screw Extruder With Cooling System --- 5. Air Conveyor --- 6. Drying Oven --- 7. Air Conveyor --- 8. Crushing Machine With Dust Pelletizing System --- 9. Air Conveyor --- 10. Blending Mixer --- 11. Packaging

The Function Of Large Nutrition Powder Process Line

- Raw Material Handling System:A large nutrition powder process line typically includes a sophisticated raw material handling system that is capable of handling a large volume of different raw materials. This system includes storage silos, hoppers, and conveyors to transport the raw materials to the processing line.

- Mixing and Blending System:A large nutrition powder process line requires a mixing and blending system that can accurately blend a high volume of raw materials to create a homogenous powder. This system may include multiple blenders or mixing vessels, and advanced mixing technologies such as ribbon blenders or paddle mixers.

- Extrusion System: The extrusion system in a large nutrition powder process line is designed to handle a high volume of product and may include multiple extruders running in parallel. These extruders are typically larger than those used in a smaller process line, and can produce a wide range of shapes and sizes.

- Drying System:The drying system in a large nutrition powder process line is typically more extensive than in a smaller line, with larger ovens or dryers capable of processing a high volume of product.

- Packaging System:The packaging system in a large nutrition powder process line is typically automated and can include multiple packaging lines to keep up with the high volume of production. The packaging equipment may include bagging machines, bulk filling machines, and cartoning equipment.

- Quality Control System:A large nutrition powder process line requires a sophisticated quality control system to ensure that the final product meets the desired specifications. This system may include in-line monitoring equipment, such as moisture sensors, as well as off-line testing equipment such as viscosity testers and colorimeters.

The Parameter Of Large Nutrition Powder Process Line

| Model | Installed Powder

(Kw) |

Powder Consumption

(Kw) |

Output

(Kg/h) |

Size

(L*W*H) |

| LY65 | 88kw | 62kw | 120-150kg/h | 19000*1200*2000mm |

| LY70 | 142kw | 99kw | 200-250kg/h | 24000*1200*2000mm |

| LY85 | 160kw | 130kw | 300-500kg/h | 28000*1500*2000mm |

| LY90 | 220kw | 154kw | 800-1000kg/h | 29000*2500*2200mm |

| LY95 | 220kw | 154kw | 1000-1500kg/h | 30000*2500*3500mm |

The Advantage Of Large Nutrition Powder Process Line

| Increased production capacity | A large nutrition powder process line allows for higher production capacity, which can meet the demands of large-scale production. |

| Consistent product quality | Large nutrition powder process lines are typically equipped with advanced equipment and technologies that ensure consistent product quality throughout the production process. |

| Efficiency and cost-effectiveness | Large nutrition powder process lines can help to streamline the production process, reduce waste, and minimize labor costs, leading to increased efficiency and cost-effectiveness. |

| Flexibility | A large nutrition powder process line can be designed to produce a variety of different products, allowing manufacturers to adapt to changing market demands. |

| Improved safety and hygiene | Large nutrition powder process lines are typically designed with safety and hygiene in mind, with features such as automated cleaning systems and strict quality control measures. |

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan