Home > Production Lines > Baby Food Production Line > 300-500Kg/h Nutritional Powder Baby Food Processing Line For Beans Milk Powder

300-500Kg/h Nutritional Powder Baby Food Processing Line For Beans Milk Powder

-

As a professional baby powder food machine supplier, our nutritional powder machines/nutritional powder production line design good manufacturing process . Baby food powder machinery can take rice flour, soybean flour, starch and others as raw materials,to make the instant nutrition rice powder for sales.

- Loyal

- ALPM-1

- Shandong China

- 1 sets/Baby Food Production Line

- T/T,L/C,D/P

- 20 days /popcorn making machine

- Wooden case or wooden pellets depended on clients' require

| Brand Name: | Loyal | Model Number: | ALPM-1 | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 sets/Baby Food Production Line | Payment Terms: | T/T,L/C,D/P | Supply Ability: | 20 days /popcorn making machine |

| Packaging Details: | Wooden case or wooden pellets depended on clients' require |

The Nutritional Powder Baby Food Processing Line is made of rice or millet as the main raw material, white sugar, vegetables, fruits, eggs, meat and other optional ingredients, and processed by adding calcium, phosphorus, iron, zinc and other minerals and vitamins. Supplementary food for infants and young children.

INTRODUCTION OF NUTRITIONAL BABY POWDER MAKING MACHINE

| Brand | Loyal | Voltage | 380V/220V/Customized |

| Power | 100kw | Product Usage | Production of nutritional powder |

| Scope of application | Snack food factory equipment, others | Feature | Automatically、Professional |

| Advantages | easy operation、energy-saving、1.2mm thick Stainless steel、High Efficiency、High Production |

PARAMETER OF BABY POWDER MAKING PROCESSION LINE

| Model | LY65 | LY70 | LY85 | LY95 |

| Power | 7KW | 25KW | 30KW | 5K5W |

| Output | 10-15Kg/h | 100-150Kg/h | 200-260Kg/h | 300-500Kg/h |

| Size(L*W*H) | 19000*1300*2200mm | 21000*1300*2200mm | 28500*3500*4300mm | 30000*1500*2600mm |

| Voltage | 380V/50HZ |

FEATURES OF NUTRITIONAL POWDER PRODUCTION LINE

The production line can be divided into semi-automated and fully automated. Due to economic growth, workers' wages are also increasing. Food manufacturers mostly use fully automatic production lines. This product can be equipped with the most suitable production equipment according to the customer's requirements and capacity according to the actual situation to achieve a win-win situation.

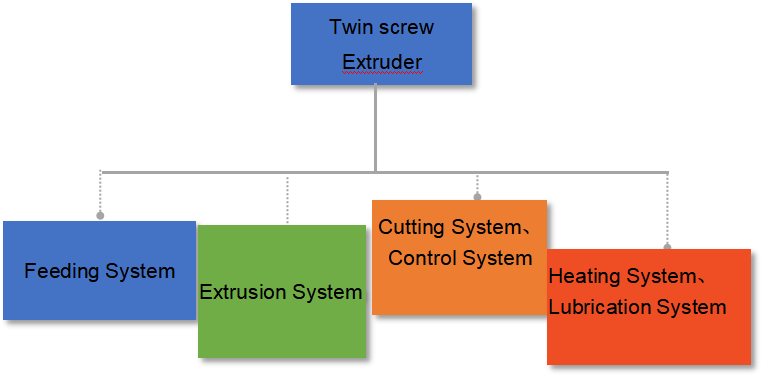

PROCESS COMPOSITION

1. Flour mixer: Mix flour and other water with a certain proportion of water and mix well.

2. Extruder: According to the output of the production line, the selected model is LY 65 extruder, the output is 100kg/h-150kg/h, the main raw materials are flour, corn flour, etc. The shape of the extruder mold and the shaper mold can be changed adjust.

3. Oven: Baking the product for a long time to make it more crispy and delicious.

4. Seasoning line: There are octagonal tube, cylinder, lifting single drum, double drum seasoning line, according to the output and product nature.

5. Crushing System: crush the baked puffed balls into nutritional powder.

NUTRITIONAL POWDER MAKING MACHINE DETAILS

Advantages For Nutritional Baby Food Process Lines

| 1 | Baby nutrition power processing line transforms the method from raw grain cooking into high-temperature and high -pressure method,and then is extruded fastly, It has characters of high automatic, easy operation. |

| 2 | Infant food machine making the rice powder food are used worldwide to nourish young children be in favor of the absorption. |

| 3 | Infant food machine enable precise cooking of raw materials allow manufacturers to process a wide range of recipes ensuring consistent quality and optimum food safety. |

| 4 | Precise control of all parameters to produce high quality products, Reduced production costs compared to traditional technologies (drum drying) |

| 5 | Compact design, reduced footprint |

| 6 | Food safety. |

QUALITY CONTROL

1. Design Control

The technical personnel carry out scientific and reasonable design according to the specific requirements of the user and the actual situation of the test, and prepare the whole process card of the equipment manufacturing.

2. Production Control

Production must be based on technical documents, the processed qualified products in each process must be marked, and the key parts must be clearly marked to ensure the traceability of the product.

3. Inspection Control

●Full-time inspectors will inspect the raw materials and outsourcing and outsourcing parts. Large batches can be sampled, but the random inspection shall not be less than 30%. The most important, precise outsourcing parts must be fully inspected.

●The processing of self-made parts must undergo self-inspection, mutual inspection, re-inspection, general inspection, and all qualified products can be regarded as qualified products.

●If the finished product can be installed and started in the factory, the test machine inspection is started in the factory, and the factory can be delivered only after the inspection is qualified; the product that cannot be installed in the factory must be strictly inspected in stages. After the installation is completed in the buyer's factory and the test machine is successful, an inspection will be issued Certificate of conformity.

NUTRITIONAL BABY POWDER PHOTOS

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Brewed nutritional meal replacement powder

Brewed nutritional meal replacement powder 7-55KW Power Nutritional Instant Porridge Processing Line Food Machinery for Rice Powder

7-55KW Power Nutritional Instant Porridge Processing Line Food Machinery for Rice Powder