Home > Production Lines > Baby Food Production Line > 7-55KW Power Nutritional Instant Porridge Processing Line Food Machinery for Rice Powder

7-55KW Power Nutritional Instant Porridge Processing Line Food Machinery for Rice Powder

-

As a professional baby powder food machine manufacturer, our nutritional powder machines/nutritional powder production line design good manufacturing process . Baby food powder machinery can take rice flour, soybean flour, starch and others as raw materials,to make the instant nutrition rice powder for sales.

- LOYAL

- Baby Food Production Line

- Shandong China

- 1 sets/Automatic Powder Packaging Machine

- T/T,L/C,D/P

- 20 Working Days /Automatic Powder Packaging Machine

- Wooden case or wooden pellets depended on clients' require

| Brand Name: | LOYAL | Model Number: | Baby Food Production Line | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 sets/Automatic Powder Packaging Machine | Payment Terms: | T/T,L/C,D/P | Supply Ability: | 20 Working Days /Automatic Powder Packaging Machine |

| Packaging Details: | Wooden case or wooden pellets depended on clients' require | Voltage: | 380V | Weight: | 850kg |

| Name: | Automatic Powder Packaging Machine | Package: | Wooden Package | Certification: | CE ISO9001 |

| Warranty: | 1 YEAR |

The baby food machine is researched and developed by our company based on the foreign advanced technology. Including Milling system、feeding system、extrusion system、heating system、transmission system and control system. The main machine is double screw extruder. LOYAL skilled engineers will go to your country to teach the workers until they can deal the line well.

PARAMERET OF NUTRITIONAL BABY POWDER MACHINERY

| Model | LY65 | LY70 | LY85 | LY95 |

| Power | 7KW | 25KW | 30KW | 5K5W |

| Output | 10-15Kg/h | 100-150Kg/h | 200-260Kg/h | 300-500Kg/h |

| Voltage | 380V/50HZ |

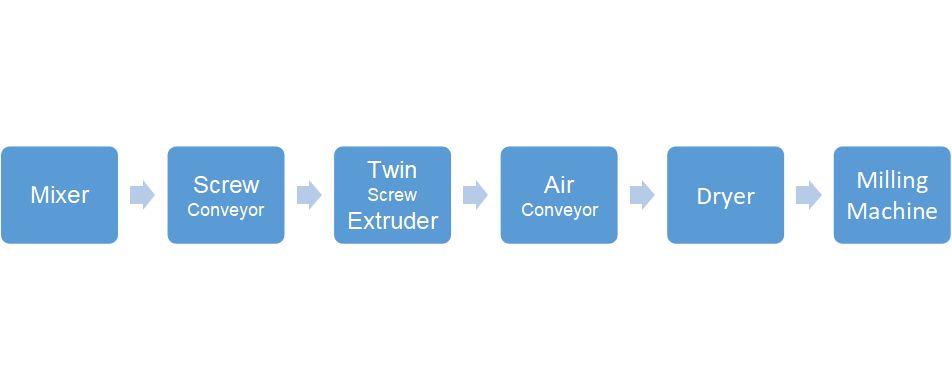

PRODUCT PROCESS DETAILED INTRODUCTION

| Name | Baby Porridge Production Line |

| Mixer | Mix the raw material full evenly. |

| Screw conveyor | Conveying the raw material into the double screw extruder. |

| Twin-screw extruder | Extruded the material, make it become the puffing food. |

| Air Conveyor | Conveying the product. |

| Dryer | Baked the product, removing the surface's water, increase storage time. |

| Milling Machine | Ground into the powder. |

| Packing Machine | Pack the production into bags. |

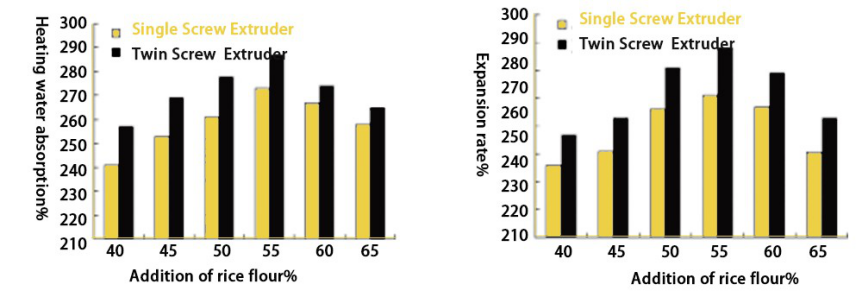

EFFECT OF SINGLE AND TWIN SCREW EXTRUSION METHOD ON COOKING QUALITY OF BABY PORRIDGE

SUMMARY OF CUSTOMER CONCERNS

SUMMARY OF CUSTOMER CONCERNS

| 1. | Raw Material | Corn, rice, millet, wheat, oats, yam, konjac, etc., with the addition of various beans such as black beans, red beans, barley, black sesame, etc |

| 2. | User | infants and young children、young and middle-aged、middle-aged、middle-aged and elderly. |

| 3. | Formula | After purchasing the machine, we will provide the basic formula. The ingredients and taste of the nutritional powder can be changed. |

| 4. | Oven Heating Method | Fuel, gas and electricity. |

| 5. | Video | Provide |

| 6. | After-Sales Installation | We have a set of after-sales installation system. |

| 7. | Customers | The customer resources are abundant, the repurchase rate is very high, and it is well received by new and old customers. |

| 8. | Layout | Our engineers will design for customers according to the layout of the customer's plant. So that the space is better used and the equipment is better placed. |

SAMPLES CAN BE MADE BY OUR BABY PORRIDGE MACHINE

ADVANTAGES OF BABY POWDER MAKING PROCESSING LINE

1. Technical aspects: The nutritional rice noodle production line adopts twin-screw extrusion technology to replace the traditional new technology of cooking rice noodles.

2. In terms of operation: The nutritious rice noodle production line integrates mixing, ripening, puffing, sterilization, and packaging, and does not require a boiler. The production process is simplified, efficient, and environmentally friendly.

3. Application aspect: The raw material of the nutritious rice flour production line can be rice flour, corn flour single material, or its mixture.

4. Product aspect: The product can be changed by changing the raw materials and auxiliary equipment, and the nutritious rice noodles produced are rich in nutrients.

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Brewed nutritional meal replacement powder

Brewed nutritional meal replacement powder 300-500Kg/h Nutritional Powder Baby Food Processing Line For Beans Milk Powder

300-500Kg/h Nutritional Powder Baby Food Processing Line For Beans Milk Powder