Home > Production Lines > Corn Flakes Production Line > Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake

Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake

-

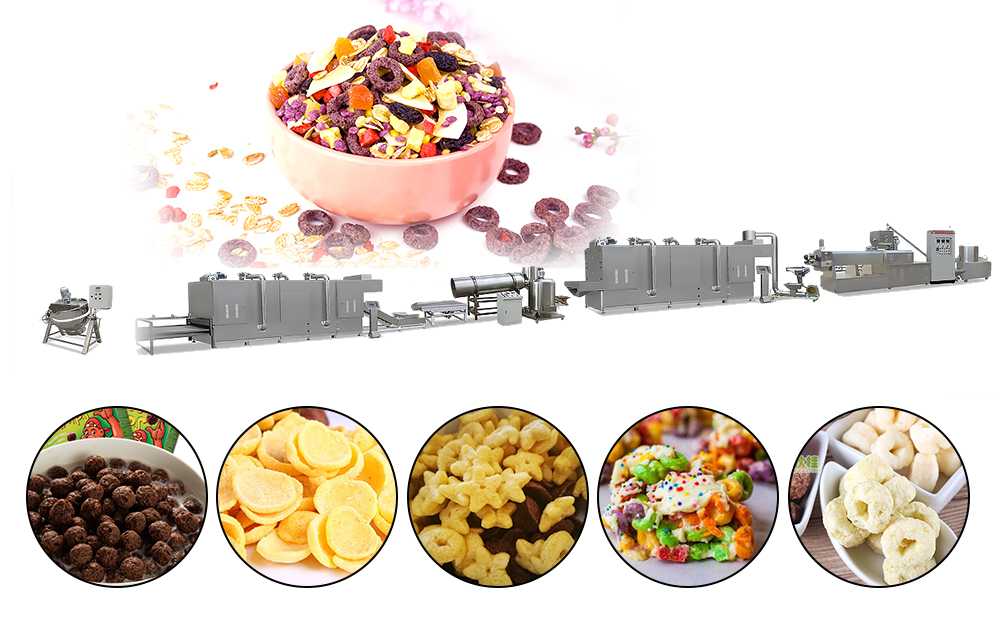

As a professional corn flakes/breakfast cereal machine supplier, our automatic corn flakes machines/corn flakes production line design good manufacturing process. Automatic corn flakes breakfast cereal machinery can take corn, wheat, oats, rice, barley, rye, Buckwheat or barley and others as raw materials, to make the corn flakes/breakfast cereal for sales.

- LOYAL

- Corn Flakes Production Line

- Shandong China

- 1 sets/Pillow Packing Machine

- T/T,L/C,D/P

- 20 Working Days /Pillow Packing Machine

- Wooden case or wooden pellets depended on clients' require

| Brand Name: | LOYAL | Model Number: | Corn Flakes Production Line | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 sets/Pillow Packing Machine | Payment Terms: | T/T,L/C,D/P | Supply Ability: | 20 Working Days /Pillow Packing Machine |

| Packaging Details: | Wooden case or wooden pellets depended on clients' require | Voltage: | 380V | Weight: | 850kg |

| Package: | Wooden Package | Automatic: | Pillow Packing Machine | Condition: | New |

| Warranty: | 1 YEAR |

Corn flakes are processed by an extruder with a special structure. Compared with the traditional method, the output, quality, and adaptability of raw materials have been improved by one step, making it possible to strengthen vitamins and minerals and other trace elements. The corn flakes production line has the characteristics of multiple models, flexible equipment configuration, wide range of raw materials, multiple product types, and simple operation. By changing different molds and changing the production process, various puffed foods popular on the market can be produced, which is suitable for various food manufacturers.

Corn flakes have a strong grain flavor and a crisp taste, suitable for all ages. It is an ideal convenient and nutritious food for office workers. The production process of corn flake extruder is simple and easy to operate.

TECHNICAL PARAMETER OF CORN FLAKES MAKING MACHINE

| Model | Power Consumption | Output |

| LY65 | 155kw | 100-150g/h |

| LY70L | 228kw | 200-250kg/h |

| LY85 | 303kw | 300-500kg/h |

| LY75 | 437kw | 500-800kg/h |

| LY95 | 555kw | 800-1000kg/h |

Corn flakes are a common breakfast cereal in the world. The raw material used to process corn flakes is hard dent corn, because of its high horny endosperm content, high transparency after starch gelatinization, and good product appearance. When eating, prepare corn flakes granules with boiling water. If corn flakes are put into the prepared soup, it can be made into corn flake soup. The corn flakes currently produced in my country include light corn flakes, sweet corn flakes and salted corn flakes. Corn contains a large embryo, which affects starch gelatinization and corn flakes morphology, and brings inconvenience to the processing operation. Therefore, corn grits that have been peeled and degerminated are used as raw materials for the production of corn flakes.

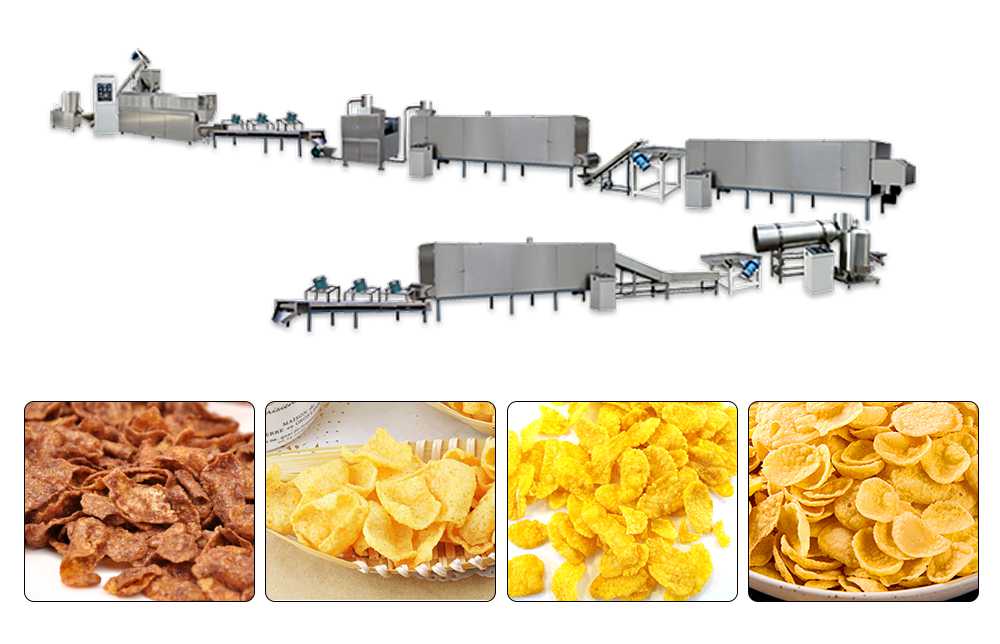

FLOW CHART OF CORN FLAKES PRODUCTION LINE Advanced industrial equipment and assembly lines have formed the following production process of Shandong Loyal breakfast cereal corn flakes production line: Corn Flour, Sugar, Salt, Other Nutrients → Mixing Ingredients → Twin-Screw Extrusion Maturation → Cutting And Forming → Pre-Drying → Flaking → High Temperature Baking → Corn Flakes.

PROCESS DESCRIPTION OF CORN FLAKES MACHINERY

| 1 | Ingredients | The ingredients of corn flakes are very important. The seasoning must have a good taste, and the ratio and content of various nutrients. |

| 2 | Extrusion Curing Molding | The extrusion curing molding process of corn flakes is the key to producing high-quality corn flakes. When producing corn flakes, the craft corn must be fully matured without any puffing. Only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor. |

| 3 | Cutting | Cut the material after extruding and curing by the twin-screw extruder into granular materials of the same size, and the material is translucent. |

| 4 | Pre-drying | The cut material enters the dryer for pre-drying, and a certain tension is formed on the surface after drying. No longer adhere to each other, which is conducive to the smooth progress of tablet compression. |

| 5 | Flaking | The flaking process is also the key to corn flake production. The requirements for the flaking machine are very high. The surface of the roll must have a high degree of smoothness, and the roll must have a constant temperature. |

| 6 | High-temperature Baking | Whether the corn flakes have a hard, brittle and compact structure. So the baking process is very important. In modern processes, high-temperature ovens are used to directly heat the air to about 260°C. |

| 7 | Cooling | The baked corn flakes become corn flakes products after cooling. And many corn flakes are processed in the post-process, coated with sugar or chocolate. And mostly based on market demand. |

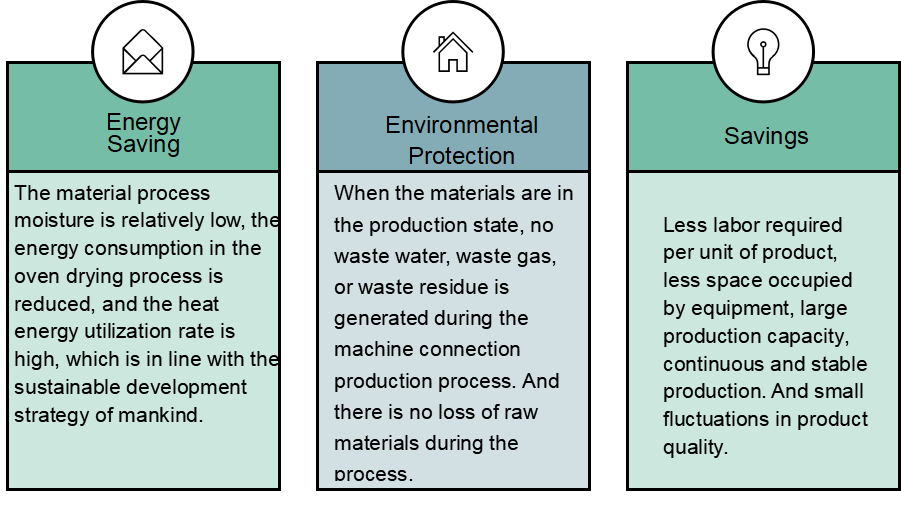

TECHNICAL ADVANTAGES OF THE CORN FLAKES PUFFED FOOD PRODUCTION LINE

LOYAL DETAILED INTRODUCTION OF IMPORTANT EQUIPMENT

| 1.Technological Advantages Of Twin Screw Extruder |

| More than 15 years of experience in researching advanced twin-screw extruders, almost all extruded products, breakfast cereals, aquatic feed, pet food, can solve any problems in production; |

| Professional focus on expanding business, serving customers wholeheartedly, responsible, serious, persevering consciousness and determination to serve users, smooth service process, establishing cooperative relationship with users beyond the project time limit, and the road to success Shandong Loyal be with you. |

2.High-speed Flaking Machine

A pair of special steel rolls rotating in opposite directions, a high-strength stand, a roll gap adjustment system, a roll cooling constant temperature system, a transmission system, and a control system.

The flaking machine has very high technical requirements for the rolls.

The surface hardness requirements are very high. If the hardness does not meet the requirements, after a period of use, the surface will be damaged, lose the smoothness, and affect the effect of the tablet. We use a special processing technology, and the surface hardness can reach 65 Above degree, the roll has a longer service life;

The processing accuracy of the roller is very high. If the processing accuracy is not up to the requirement, it will cause uneven sheeting, large vibration and high noise. We strictly control the processing during processing, and the cylindrical degree of the roller is guaranteed to be 3μm.

There is a cooling water channel inside the roll, and the pressured water pipe is connected to form a circulating water-cooled press roll constant temperature control system to ensure that the roll is always at a constant temperature when the tablet press is working.

| 3.Hot Air Dryer |

| The belt dryer is composed of several layers of conveyor belts, heating devices, transmission devices, heat preservation devices, racks and control systems. The performance of the dryer directly affects the quality and value of the dried food. |

| The belt dryer has strong pertinence, practicability, and high energy efficiency. It is widely used in snack food drying, high temperature roasting, and feed drying. It is deeply applied to the dehydration and drying of various regional and seasonal vegetables and fruits. , Covers grain drying, feed pellet drying, etc. |

4.Sugar Spray Seasoning System

The sugar sprayer uses an advanced electromagnetic diaphragm pump for raw material output. The spraying flow rate can be adjusted more intuitively. The sprayed liquid is combined with the product in a single drum. The drum rotates with the animal material to roll, so that the liquid sprayed on the product surface is even and smooth.

(1)The amount of sugar spray can be adjusted freely.

(2)Can spray sugar on the surface of the product.

(3)The conveyor belt adopts stepless speed regulation to meet various specifications and models.

(4)The sugar hopper water heating has automatic adjustment and constant temperature control mechanism, so that the sugar in the sugar hopper will not crystallize.

(5)he spouted sugar is like snowflakes, increasing people's purchase demand.

PHOTOS OF CORN FLAKES

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Introduction about corn flakes production line

Introduction about corn flakes production line Stable Pre-Formtion Corn Flakes Manufacturing Cereal Production Line Processing Line

Stable Pre-Formtion Corn Flakes Manufacturing Cereal Production Line Processing Line