Home > Production Lines > Corn Flakes Production Line > Stable Pre-Formtion Corn Flakes Manufacturing Cereal Production Line Processing Line

Stable Pre-Formtion Corn Flakes Manufacturing Cereal Production Line Processing Line

-

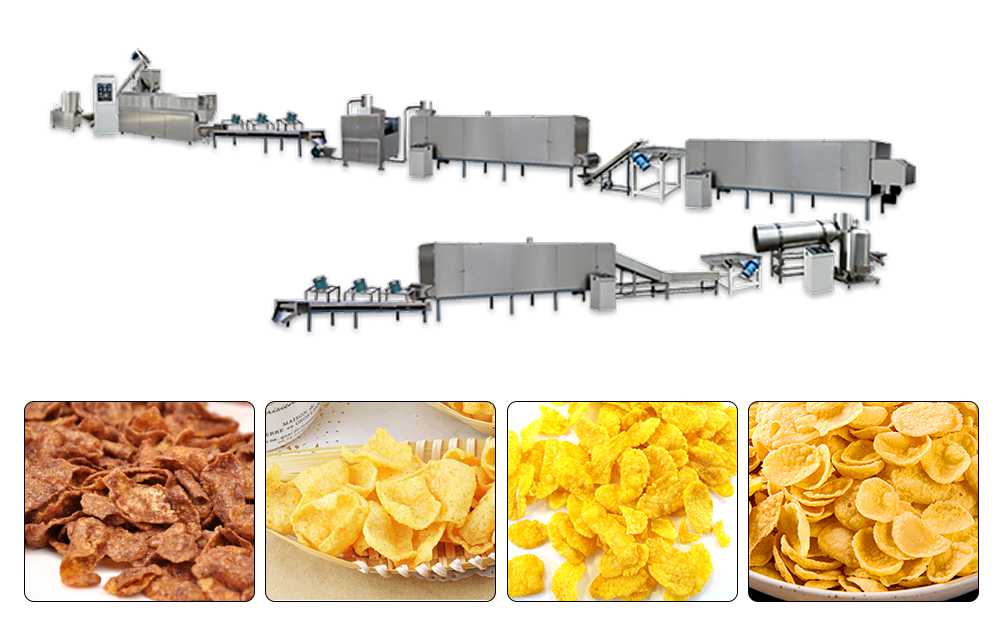

As a professional corn flakes/breakfast cereal machine manufacturer, our automatic corn flakes machines/breakfast cereal production line design good manufacturing process. Automatic corn flakes breakfast cereal machinery can take corn, wheat, oats, rice, barley, rye, Buckwheat or barley and others as raw materials, to make the corn flakes/breakfast cereal for sales.

- Loyal

- IPM-2019

- Shandong China

- 1 sets/Corn Flakes Production Line

- T/T,L/C,D/P

- 20 days /Industrial Popcorn Machine

- Wooden case or wooden pellets depended on clients' require

| Brand Name: | Loyal | Model Number: | IPM-2019 | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 sets/Corn Flakes Production Line | Payment Terms: | T/T,L/C,D/P | Supply Ability: | 20 days /Industrial Popcorn Machine |

| Packaging Details: | Wooden case or wooden pellets depended on clients' require | Voltage: | 380V | Dimension(L*W*H): | 7100X1100X1400mm |

| Weight: | 850kg | Condition: | New | Package: | Wooden Package |

| Function: | Multifunctional | Automatic: | industrial popcorn poppe |

Breakfast cereal is a breakfast food with high nutritional value. They usually use corn flour and other grains as the main raw materials. And they are mixed, squeezed, pressed, dried, baked at high temperature, coated with sugar. Then cooled to make crispy and sweet chips. Breakfast cereals are mainly used for breakfast with milk coffee. And it can also be used as casual snacks. This fully automatic breakfast cereal production line can produce breakfast cereal products of various shapes. Such as circle shape, small ball, moon shape, etc.

LOYAL MODEL POWER CONSUMPTION OUTPUT

| Model | Power Consumption | Output |

| LY65 | 155kw | 100-150g/h |

| LY70L | 228kw | 200-250kg/h |

| LY85 | 303kw | 300-500kg/h |

| LY75 | 437kw | 500-800kg/h |

| LY95 | 555kw | 800-1000kg/h |

RAW MATERIAL OF CORN FLAKES BREAKFAST CEREAL MACHINERY Corn powder, rice powder, wheat flour, oat flour (you can add other materials as you like). CHANGE THE DIE CAN MAKE DIFFERENT SHAPE Round balls, rings, flower, heart shape, starts, animals, alphabetic ABC or 123. Etc.

PRODUCTION PROCESS OF CORN FLAKES BREAKFAST CEREAL Flour Mixer-Screw Conveyor-Double Screw Extruder- Air Conveyor-Drying Machine- Sugar Sprayer- Drying Machine-Cooler

| Flour Mixer | Mixing the raw materials. |

| Screw Conveyor | 1.Screw conveyor can not only convey on the level but also by any angel these materials can be conveyed in the stainless steel roller without leaking, dust pollution; 2.Meanwhile it can send the self-mixer to the feeding machine or the conditioner and directly send the discharge hole of the inflating extruder. |

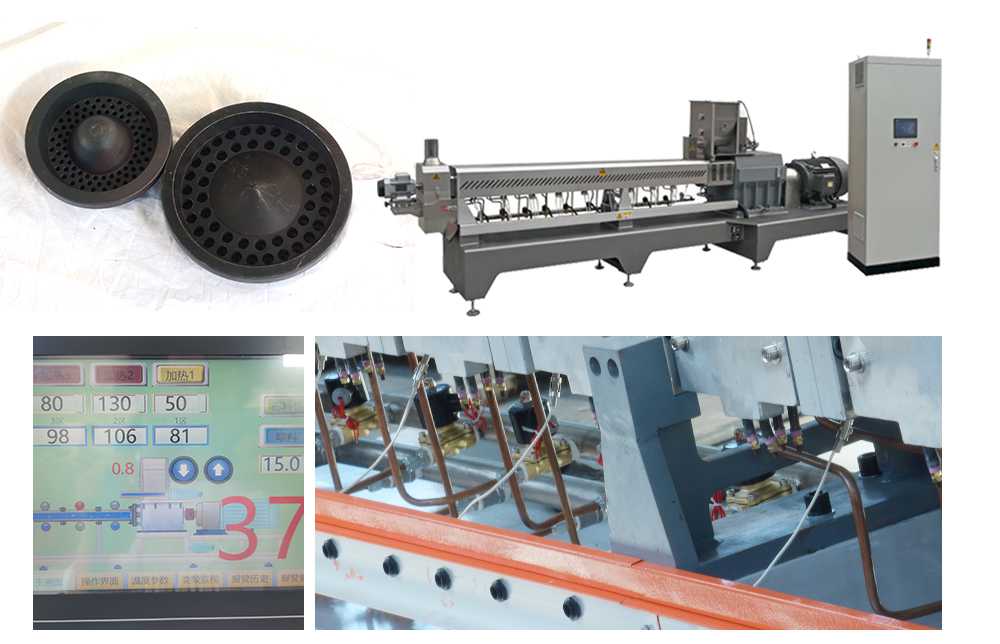

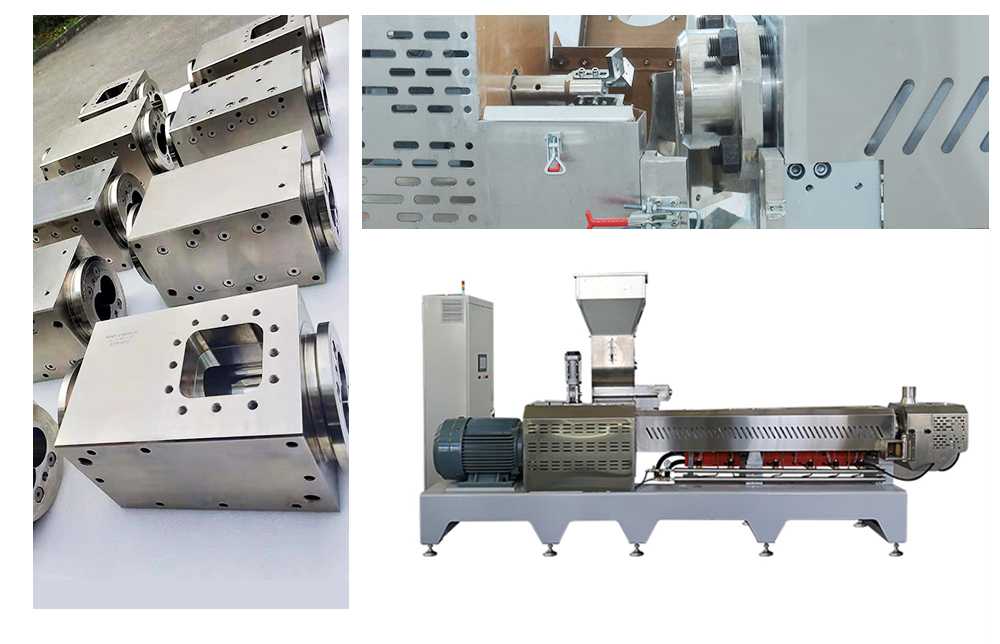

| Double Screw Extruder | 1. The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer. 2. Adopting the building block structure and combining willingly according to the different demand. 3. The forced lubrication system, so that it can guarantee the equipment transmission life longer 4. Auto-temperature control system; make the temperature controlling more direct viewing and the parameter more precise.5. Self-cleaning, when stopping, it can be cleaned without disassembling |

| Air Conveyor | Used to carry products to the next device. |

| Drying Machine | 1.Aluminum Silicate as thermal insulation materials inside the body cover2.This kind of oven has a wide range of application. It can dry all shapes of puffing food, including strip, lump, granular materials etc, as well as other types of materials. Users can choose different types with different layer, length, and heating mode.3.It has compact design and easy operation.4.The oven is droved with double pitch roller chain and heats materials circularly. It runs smoothly, never obstruction.5.Roasting temperature and time can be adjusted, effect of roasting is perfect.6.With high efficiency fuel saving system, reasonable heat distribution, material is heated equally, low energy but large output. |

| Sugar Sprayer | Spray sugar、honey or chocolate on the surface of breakfast cereals. |

| Drying Machine | Dry the breakfast cereal after spraying sugar 、honey or chocolate again. |

| Cooler | Cool the breakfast cereals coming out of the oven. |

ADVANTAGES OF MAIN MACHINE

| Twin Screw Extruder | 1.Using building block screw.2.Simple and easy to maintain and clean3.The control cabinet is simple and easy to operate.4.Greater flexibility, with the capability to process a wide range of raw materials5. Intelligent recipe memory.6. Increased productivity due to continuous processing, faster start up and shut down between product changes, quick changeover and advanced automation. |

| Drying Machine | 1. The special structure of the penetration oven is convenient for maintenance and cleaning.2. The box body adopts double-layer aluminum silicate insulation board.3. The pipeline adopts aluminum silicate insulation layer.4. Multiple groups of hot air blowers blow high-temperature hot air from the upper and lower parts of the material to the material, and the baking is even.5. Each group of hot air blowers has independent air outlet duct and return air duct, which has higher thermal efficiency. |

CUSTOMER CONCERNS Breakfast cereal recipe: After purchasing the machine, we will provide the basic formula. Breakfast cereal production line installation: We will arrange engineers to go to the customer's factory to guide the installation. Factory layout: We will design the layout of the breakfast cereal production line for the customer according to the size of the customer's factory. Oven heating methods: Electricity, diesel and gas, these three heating methods are for customers to choose. Factory: If the customer cannot visit the factory in person, we will arrange a video conference to visit our factory. Certificate:CE、ISO9001、SGS、BV.

CORN FLAKES PHOTOS

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Introduction about corn flakes production line

Introduction about corn flakes production line Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake

Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake