Home > Production Lines > Soya Meat Making Machine > 11-20kw Automatically Textured Vegetable Protein TVP Line Machine 600-1000kg/h

11-20kw Automatically Textured Vegetable Protein TVP Line Machine 600-1000kg/h

-

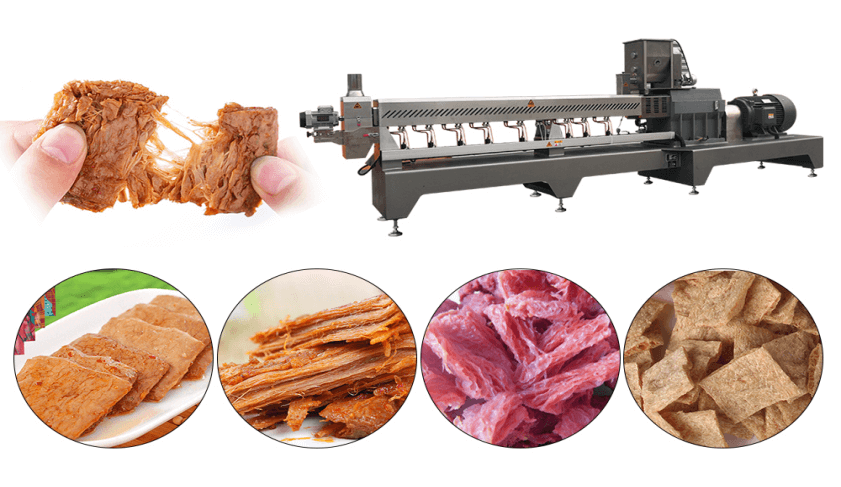

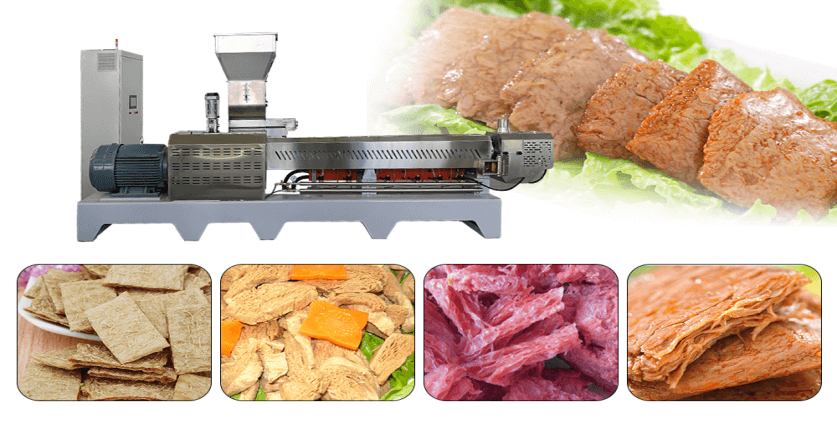

As a professional textured vegetable TVP line manufacturer, our double screw extruded soya protein making machine design good manufacturing process. Texture soya protein food making machinery can take corn flour, wheat flour, and others as raw materials, to make the high nutrition soya chunks food for sales.

- Loyal

- TVP 52 TVP 70 TVP 75 TVP 90

- Shandong China

- 1 set/soya nuggets fully automatic plant

- L/C,T/T,D/P

- 25 days /soya nuggets manufacturing plant

- Wooden case or wooden pellets depended on clients' requirement

| Brand Name: | Loyal | Model Number: | TVP 52 TVP 70 TVP 75 TVP 90 | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 set/soya nuggets fully automatic plant | Payment Terms: | L/C,T/T,D/P | Supply Ability: | 25 days /soya nuggets manufacturing plant |

| Packaging Details: | Wooden case or wooden pellets depended on clients' requirement |

Texture Soya Meat Making Machine is the new extruder we specially designed for plant protein extrusion. Automatically textured vegetable protein tvp line which processes low temperature soya bean powder and peanut meal to meat-like food that can be added to ham, sausage, fast food and deep freeze food for more taste.

| NAME | Automatically Textured Vegetable Protein TVP Line |

| Item NO. | Detail Description |

| 1 | Soya protein food processing line uses soybean powder and peanut powder to break spherical protein molecule to form chain protein molecule . |

| 2 | The texture soya protein food made by soya protein production process is nutritious without cholesterol or animal fat, but it looks like and tastes like meat with the quality of absorbing soil, water, and flavor. |

| 3 | This kind of food has high nutrition and can be widely applied in many industries: ham, cam, fast-food, instant-cool food etc. |

| 4 | The complete automatically textured vegetable protein manufacturing processing line includes Mixer, extruder, dryer and cooling machine. |

HOW IS SOYA PROTEIN FOOD MADE IN FACTORY ?

Automatically textured vegetable protein tvp line using soya pea, etc plant type protein as main materials, after extruded, finished product with good water absorption fiber extensively. So far best substitution for animal meat, free cholesterol, high protein. Widely used at vegetarian client fast freezing food, sausage food.

Raw material: corn flour, wheat flour and other grain flour

Capacity: 15-40kg/h, 80-120kg/h, 200-500kg/h, 600-2000kg/h

Energy: electricity, gas, steam

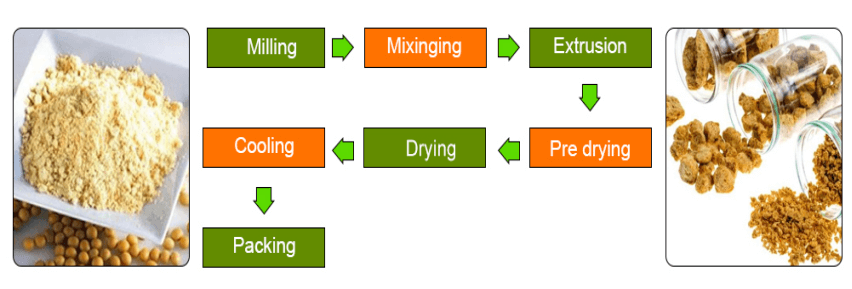

EXTRUDED SOYA NUGGETS PROCESSING TECHNOLOGY FLOW

Mixer-Screw Conveyor- Double Screw Extruder- Air Conveyor- Dryer- Hoister- Cooling Machine

AUTOMATICALLY TVP PRODUCTION MANUFACTURING PROCESS FEATURES

| Item No. | Features Description |

| 1. | Various models to meet different output capacity requirements. |

| 2. | Flexible configurations to meet different produce, budget and workshop layout requirement. |

| 3. | Vast raw material range to produce different final products by only one production line. |

| 4. | Different shapes and appearances of final products can be made by changing different modules in double screw extruder. |

| 5. | High automation and accurate control system to save labor cost and improve the quality of final products. |

PROFESSIONAL SOYA CHUNKS PRODUCTION LINE DESIGN

LOYAL engineer could design the layout drawing according to your dimension of the factory for the proteins machines.

TECHNICAL PARAMETER OF SOYA CHUNK PRODUCTION LINE

| Model | Screw Size | Power | Capacity |

| LY36 | 36mm | 11-20kw | 15-40kg/h |

| LY50 | 50mm | 37-55kw | 80-120kg/h |

| LY72 | 72mm | 75-132kw | 200-500kg/h |

| LY95 | 95mm | 132-200kw | 600-1000kg/h |

| LY120 | 120mm | 160-450kw | 800-2000kg/h |

APPLICATIONS OF AUTOMATIC TEXTURED SOY PROTEIN MACHINE

Usage of the textured soybean protein production line: Sausage, Dumplings, Burger, Vegetarian meat, Cook for dishes directly, etc;

Dry Textured soya protein Pellets, Crumbs, Minced, Flakes, Soya Chunks, Chips ,Schnitzel, Soya Nuggets, Suya burgers.

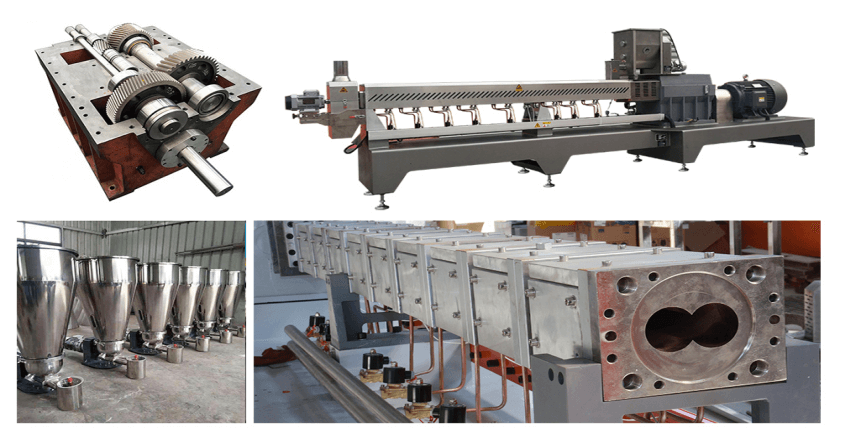

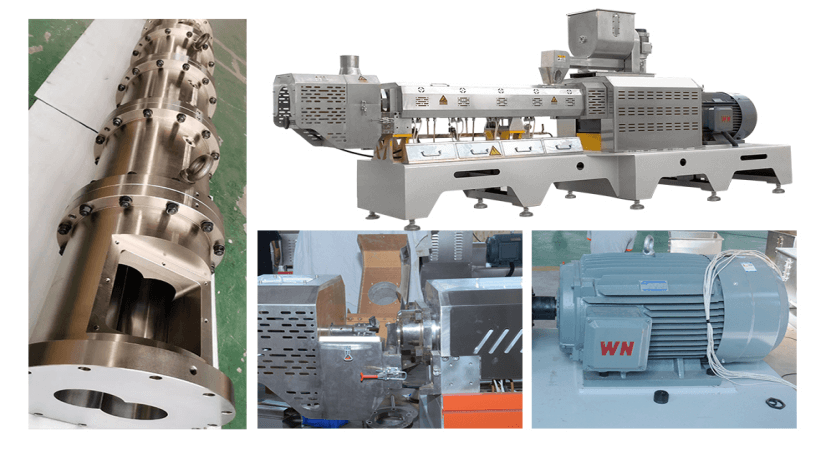

MACHINE PHOTOS OF PROFESSIONAL SOYA BEAN MEAT PROTEIN/ TSP PRODUCTION LINE

| Combination screw | The double screws made of high strength and durable hard alloy steel, twin screw extruder design can also more effectively change the screw element combination and for various material compounding.it can make different type products by combination screw; longer using time. |

| Extruder barrel | The barrel is made with bushing and cylinder, bimetallic treatment. The screw and barrel of double screw extruder machine adopt segmented design. Different combination of barrel decide the extruder L/D; different combination of screw decide the extruder function. |

| PLC control | Better control of process parameters, that are: narrower residence time distribution, lower dispersion of shear rates and strain, higher convective heat transfer, accurate control of temperature profile; hence leading to much better control of shear-time-temperature histories in the extruder, to much wider range of mechanical energy inputs, and so to more consistency in regards to material conversion and product quality. |

| Distribution box | Distribution box including automatic lubricating system, filtration system and cooling system; Gear box, adopt alloy steel, bearing units is imported. Automatic lubricating, filtration and cooling system. |

| Cutting system | Cutting system connects the motor directly, easy cutting, changing the mould seat freely, meeting different products demands, inverter adjusting the speed, product size adjustable. |

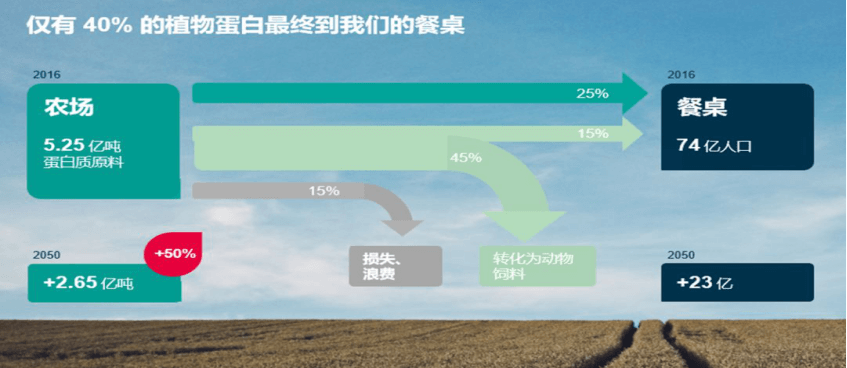

Tissue Protein VS. Meat Products

The advantages of tissue protein:

| High efficiency | The conversion rate of plant tissue protein can reach more than 75%. Bring protein raw materials to the table more directly, these can be made by plant tissue protein |

| Safe | Zero cholesterol, zero antibiotics |

| Nutrition | According to the physical needs of different people, tissue protein can be tailored to prevent uneven nutrition |

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

800-2000kg/h Soyabean Badi Making Machine With Double Screw Extruder

800-2000kg/h Soyabean Badi Making Machine With Double Screw Extruder Soya Protein Making Machine Extruded Soy Nuggets Production Line 55-110kw

Soya Protein Making Machine Extruded Soy Nuggets Production Line 55-110kw