Home > Production Lines > Soya Meat Making Machine > 800-2000kg/h Soyabean Badi Making Machine With Double Screw Extruder

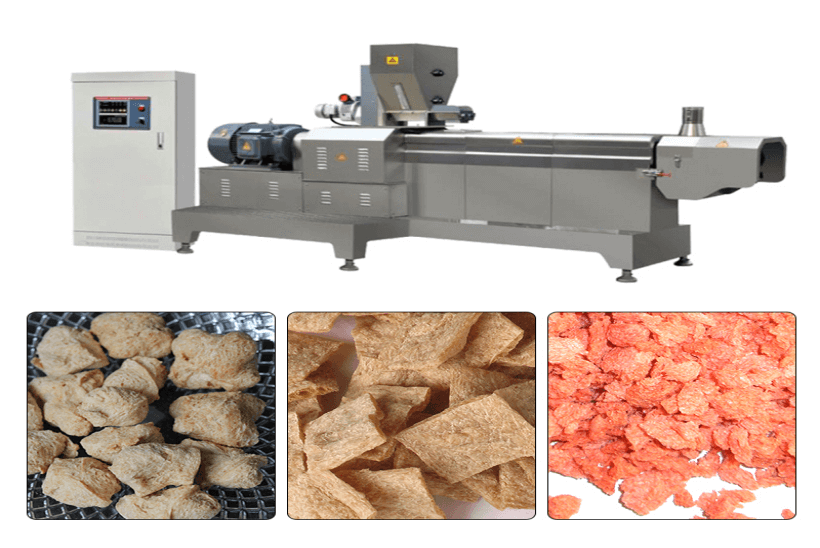

800-2000kg/h Soyabean Badi Making Machine With Double Screw Extruder

-

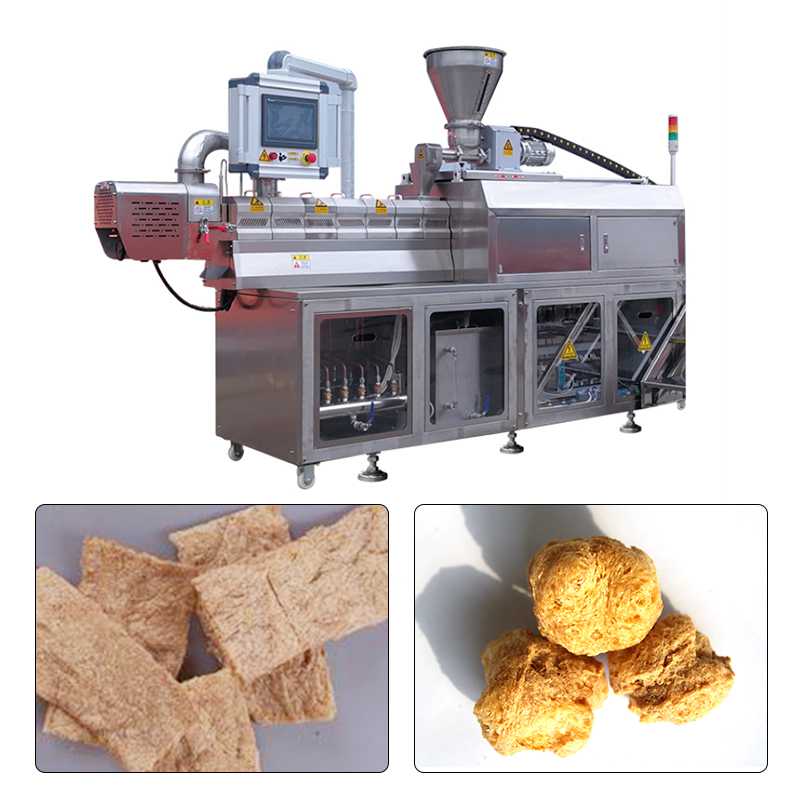

As a professional soyabean badi food making machine manufacturer, our autocratically soya chunks food production line design good manufacturing process. Protino soybean badi machinery can take rice flour, soybean flour, and others as raw materials, to make the delicious soya chucks food for sales.

- Loyal

- TVP 52 TVP 70 TVP 75 TVP 90

- Shandong China

- 1 set/soya nuggets fully automatic plant

- L/C,T/T,D/P

- 25 days /soya nuggets manufacturing plant

- Wooden case or wooden pellets depended on clients' requirement

| Brand Name: | Loyal | Model Number: | TVP 52 TVP 70 TVP 75 TVP 90 | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 set/soya nuggets fully automatic plant | Payment Terms: | L/C,T/T,D/P | Supply Ability: | 25 days /soya nuggets manufacturing plant |

| Packaging Details: | Wooden case or wooden pellets depended on clients' requirement |

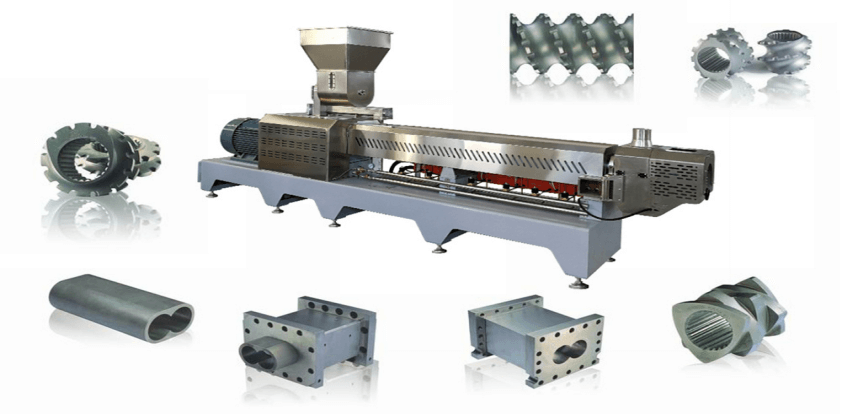

Texture soya protein food making machinery uses the newest production equipment which is researched and developed according to the market demand and country's basic condition. Soyabean badi making machine uses the soybean and the peanut as the raw material and makes the round protein moisture become the chain shape and reorganization then form the sheet fibre structure by grinding, mixing, conditioning, high temperature, high pressure and high cutting. Soya chunk production line is include mixer, double screw extruder, the shaping machine, dryer, the cooling machine.

DETAIL DESCRIPTIONS OF EXTRUDED SOY NUGGETS PRODUCTION LINE

| Raw materials | Adopts defatted soya flour as raw materials. |

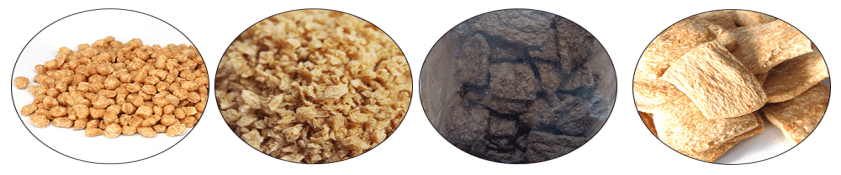

| Products | Soyabean badi making machine can be used to produce soya nuggets, TVP/TSP, soya chunks, Soya burgers, Protino Soybean Badi by adjusting the moulds from extruder; meanwhile it can produce cereal, snacks by adjusting the screws from double screw extruder. |

| Certificate | CE,GOST,TUV,BV |

| Capacity | 15-40kg/h, 80-120kg/h, 200-500kg/h, 600-1000kg/h, 800-2000kg/h |

| Voltage | Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local power supply. |

| Machines materials | All the machines are made by stainless steel. |

| Energy Source | Energy: Electricity, gas, steam. |

TECHNICAL PARAMETER OF EXTRUDED SOY NUGGETS PRODUCTION LINE

| Model | Screw Size | Power | Capacity |

| LY36 | 36mm | 11-20kw | 15-40kg/h |

| LY50 | 50mm | 37-55kw | 80-120kg/h |

| LY72 | 72mm | 75-132kw | 200-500kg/h |

| LY95 | 95mm | 132-200kw | 600-1000kg/h |

| LY120 | 120mm | 160-450kw | 800-2000kg/h |

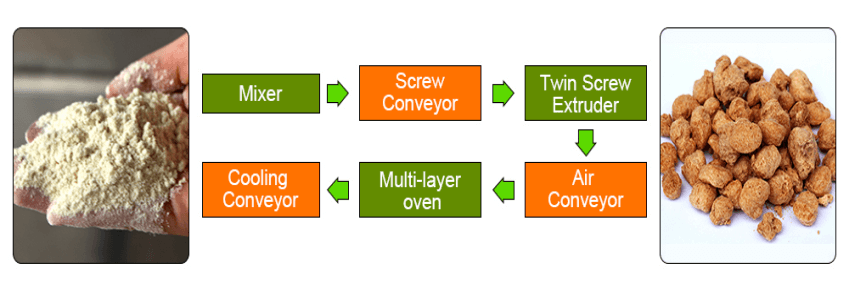

AUTOMATICALLY SOYA PROTEIN MAKING MACHINE PRODUCTION PROCESS

Flour Mixer-Screw Conveyor-Twin Screw Extruder- Air Conveyor- Dryer- Hoister- Cooling Machine

The Main Equipment Using In The Soyabean Badi Making Machine Processing

| Item No. | Main machine | Details Description |

| 1. | Flour Mixer | To mix defeated soya bean powder with water. |

| 2. | Twin Screw Extruder | To cook the soya bean powder and extrude in different shapes. |

| 3. | Air conveyor | Take the extruded products into oven or drying machine |

| 4. | Dryer | Drying extruded products |

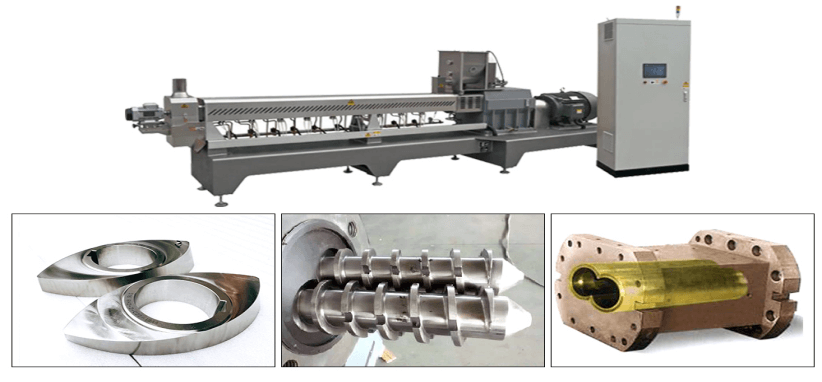

DETAILS & FEATURES OF TSP MAKING MACHINE

1. The screw is made of alloy by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. Soyabean badi making machine adopts speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine guarantees stable materials feeding in the whole food process.

3. The gearbox has automatic lubrication function, with extends gear life.

4. Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely. 5. Barrel with water-cooled circulation. Different moistur extrusion temperature ratio, whole-expanded and half expanded as different type of products. 6. High automation and accurate control system to save labor cost and improve the quality of final products. 7. Flexible configurations to meet different produce, budget and workshop layout requirement.

APPLICATIONS OF AUTOMATIC SOYA BEAN MEAT PROTEIN FOOD PRODUCTION LINE

(1)Dry Textured soya protein Pellets, Crumbs, Minced, Flakes, Chunks, Chips ,Schnitzel, Nuggets. (2)High moisture wet protein Soya,pea, Pea-sunflower THE ADVANTAGES OF TEXTURE SOYA PROTEIN FOOD MAKING MACHINERY PROCESS

| Item No. | LOYAL Detail description of industrial automatically textured vegetable protein tvp line process |

| 1 | Screw made by nit-riding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials. |

| 2 | Adopting speed adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process. |

| 3 | Gearbox with automatic lubrication function, extending gear life. |

| 4 | World famous brand Siemens main motor, guaranteeing good quality. |

| 5 | Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely. |

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

11-20kw Automatically Textured Vegetable Protein TVP Line Machine 600-1000kg/h

11-20kw Automatically Textured Vegetable Protein TVP Line Machine 600-1000kg/h Soya Protein Making Machine Extruded Soy Nuggets Production Line 55-110kw

Soya Protein Making Machine Extruded Soy Nuggets Production Line 55-110kw