Home > Production Lines > What is instant noodles production line?

What is instant noodles production line?

-

Introduction: Instant noodles, also known as fast food noodles, cup noodles, fast cooked noodles, are generally called bowl noodles in the south and doll noodles in Hong Kong. It is a noodle product that can be cooked in hot water within a short period of time. In a broad sense, it refers to a kind of […]

- JinanShandong

- 1 set

- T/T;L/c

- QingdaoChina

| Place of Origin: | JinanShandong | Min.Order Quantity: | 1 set | Payment Terms: | T/T;L/c |

| Port: | QingdaoChina |

Introduction:

Instant noodles, also known as fast food noodles, cup noodles, fast cooked noodles, are generally called bowl noodles in the south and doll noodles in Hong Kong. It is a noodle product that can be cooked in hot water within a short period of time. In a broad sense, it refers to a kind of noodle food that can be soaked and cooked in hot water within a short period of time, with related dishes such as homemade noodles and noodle salad; in a narrow sense, instant noodles usually refer to finished products sold in bags and cups or bowls, consisting of noodle cakes, seasoning packets and oil packets. Ando Momofuku invented instant noodles in 1958, and with the accelerated pace of life and the need to travel, instant noodles have become one of the easy foods indispensable to modern life.

Instant noodles are ready-to-eat convenience foods that are made by steaming and deep-frying shredded noodles to a fixed shape (usually square or round), brewing them in boiling water before serving, dissolving the seasoning and heating the noodles to brew them open and serve them in a short time (usually within 3 minutes).

Today, various brands of instant noodles fill the shelves of major shopping malls, from large retail supermarkets to small street shops.

The Production Line Details :

| Capacity | 11000 bags/8h; 30000 bags/8h; 60000 bags/8h; 80000 bags/8h; 100000bags/8h |

| Electricity supply | Customized according to your local electricity situation. |

| Machine details | 1. Stainless steel,:201, 304, 316, on request.

2. Electrical components can be ABB, Delta, Fuji, Siemens; famous brands. |

| Certificates | CE,GOST,TUV,BV |

| Raw material | flour, vegetable oil, water, salt and other chemical additives |

| Product colour | White; green; purple; yellow and other colours |

Flow Chart of instant noodles production line:

Instant noodles are available in both large and small production volumes, as well as fried and non-fried options.

Small capacity: 1. Dough Maker-----2. Compound and Shaping machine-----3. Boiling machine-----4. Cutting machine-----5. Fryer-----6. Cooling machine

Large capacity: 1. Alkali water mixing tank-----2. Alkali water measuring device-----3.Flour mixer-----4. Round disk aging machine-----5. Rolling&shipping machine-----6. 3 layer steaming machine-----7. Noodle cutting and dividing machine-----8. Fryer-----9. Oil tank -----10. Arranging machine-----11. Cooling machine-----12. Conveyor machine-----13. Spare parts and tools-----14. Bag packing machine-----15. Flavoring powder packing machine-----16.Gas steam boiler

Non-fried instant noodle production: 1.Round disk aging machine-----2. Alkali water measuring device-----3. Rolling Shaping Machine-----4. 3 layer steaming machine-----5. Cutting and sorting machine------6. Continuous drying oven-----7. Arranging machine------8. Air cooling machine-----9. Distributing conveyoring machine-----10. Checking conveyor-----11.Packing machine

Feature Of instant noodles production line:

- High degree of automation: Ithas a very high degree of automation, which can well meet the needs of customers and fully meet the needs of various enterprises.

- Large output: It can realize multiple batch processing, thus avoiding problems such as equipment downtime and long downtime due to different batches. The output of the equipment is large, thus ensuring the production efficiency and quality. At the same time, the production speed of the equipment is fast, and the output can be adjusted at any time according to the output needs of different users.

- Low energy consumption: It can effectively reduce the utilization rate of energy and achieve the purpose of saving costs.

- Sanitation and cleaning: The equipment adopts a new type of dust removal equipment, which can well avoid dust pollution to the surrounding environment and ensure environmental hygiene. In the process of processing,a certain amount of dust will be generated. If the dust is not effectively removed, the dust will cause harm to the health of the workers.

- Easy to operate: The device is easy to operate and easy to use, whether it is a small-scale enterprise or a large-scale enterprise, it can be easily used.

The above are the characteristics of the bread crumb production line. This equipment has the advantages of large output, high efficiency and low energy consumption, and can meet the needs of various customers.

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

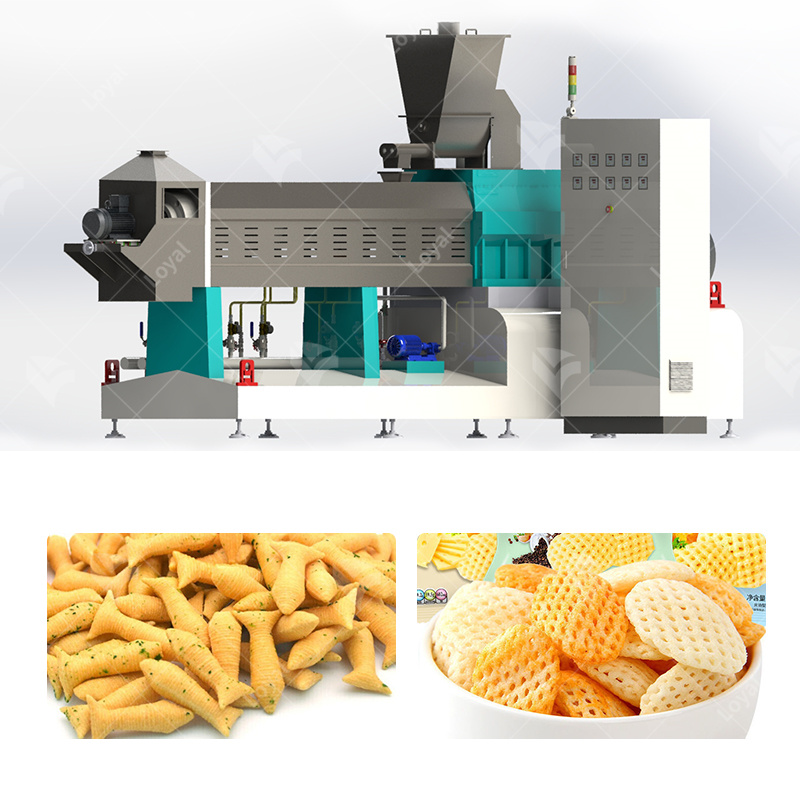

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

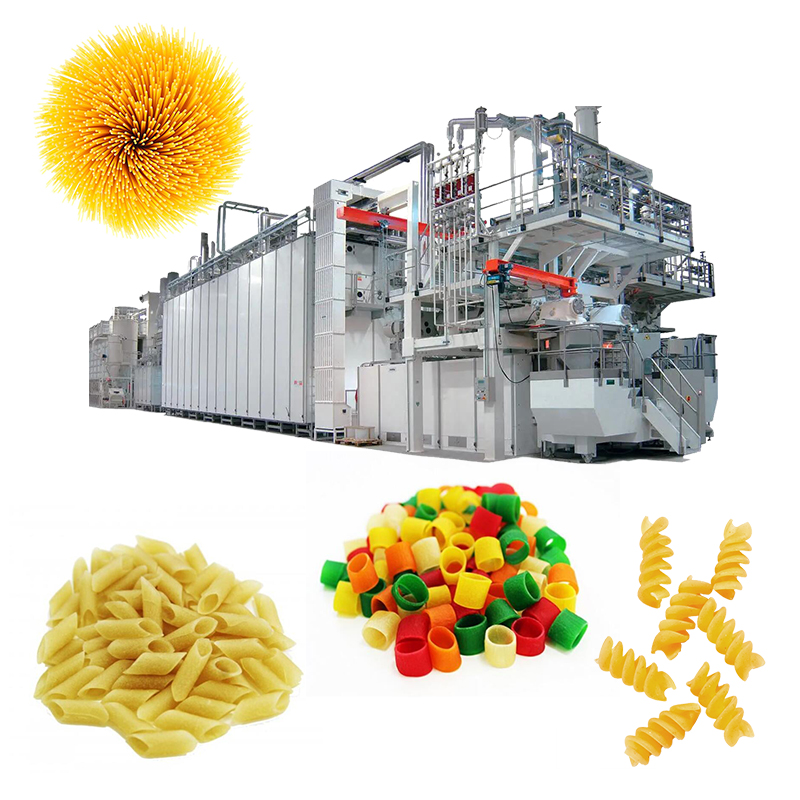

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Industrial microwave drying equipment

Industrial microwave drying equipment Fully automatic bread crumb production line

Fully automatic bread crumb production line Introduction to macaroni and cheese

Introduction to macaroni and cheese About the puffed food machine

About the puffed food machine