Home > Technical Blog > How does a production line work?

How does a production line work?

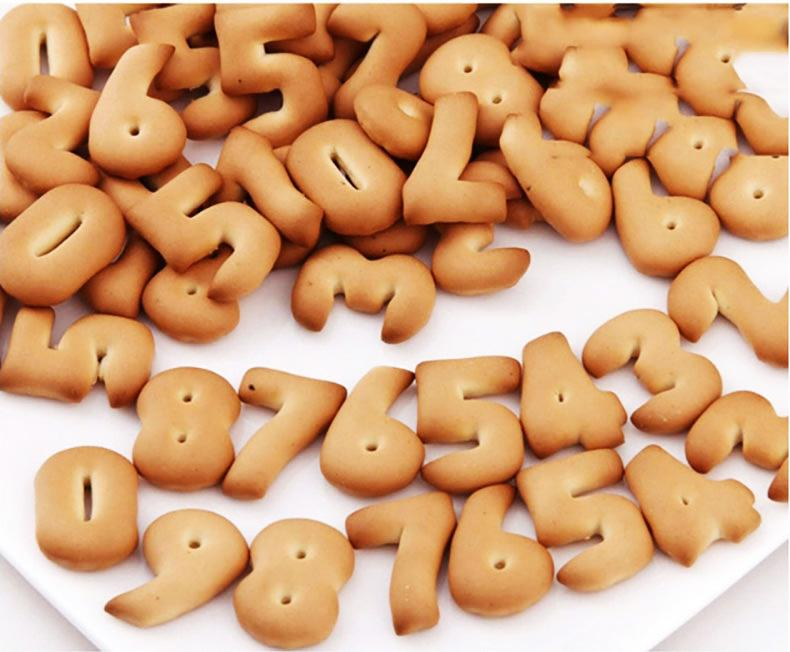

June 9, 2021Biscuit Production Line can make many different types of biscuits. Such as butter biscuits. Sandwich biscuits. Soda biscuits. Vegetable biscuits, etc. There are a variety of heating sources for your operation (Electricity. Gas. Fuel oil). The stable performance biscuit machine provided by our company. From raw material mixing. Molding to baking. We provide customers with a full set of configurations. Saving customers time.

Many people have questions about the process of production line work. So how does a production line work?

The technological process of the biscuit production line: flour. Auxiliary materials—>dough preparation—>tabletting—>rolling forming—>baking—>oil injection—>cooling—>finished product

The production line refers to a form of production organization in . Which the product process is realized by an automated machine system. Biscuit raw materials are automatically transferred from one machine tool to another. And processed. Loaded . Unloaded. And inspected by the machine tool. The worker's task is only to adjust. Supervise and manage the automatic line. It does not participate in direct operation. All machines and equipment are in accordance with Uniform tempo operation. And the production process is highly continuous.

As we all know, the biscuit production line is composed of a biscuit forming machine. A tunnel-type hot air circulation electric oven. A fuel injection machine. A turning machine. A cooling line. A biscuit sorting machine. Abiscuit sandwiching machine. And a packaging table. Choosing the fully automated Biscuit Production Line. It can help you make better profits in the biscuit business.

The entire Biscuit Production Line of our company adopts CPU module control. Back-mounted motor drive. Compact structure. High degree of automation. From feeding. Three-stage pressing. Forming. Sugar screening. Conveying. Waste. And recycling.

All the electromechanical integration of baking. Fuel injection. Cooling, etc. is completed automatically. The biscuit production line is novel in design. Compact in structure. And highly automated. From feeding to calendering, forming. Waste recycling. Drying. Oil spraying. And cooling. It can be fully automated at one time.

The above professional technical issues are all pointed out by the cost-effective food machinery technical article in 2021.

The choice of the biscuit production line determines your best profit in the biscuit business. What are the features and functions of the Biscuit Production Line?

- All kinds of machinery on the automatic biscuit production line are equipped with frequency conversion speed regulation. And all kinds of machinery cooperate with each other tacitly. And truly realize automation.

- The automatic biscuit machine occupies a small area and consumes less. So small workshops can easily start production.

- The automatic biscuit machine has many types of molds and product designs. One machine can produce short biscuits. Hard biscuits. Chocolate biscuits. Such as butter biscuits, sandwich biscuits. Soda biscuits. Animal biscuits. Vegetable biscuits. And biscuit making machines can continuously produce 24 hours a day.

- The full-automatic biscuit machine requires fewer workers. And the dry forming machine is frequency-converted and linked. The operation is simple and quick. And the workers can get started quickly. Only 2-3 workers can complete the whole process from raw material mixing to packaging. The operation is simple. After training, workers can easily operate the machine.

- No industrial pollution. No waste. And environmental health protection.

To

The automatic biscuit production line makes it simple and convenient to produce delicious biscuits. It not only reduces a lot of intermediate links. But also reduces a lot of manual operations. The automatic integration of biscuit production has been realized. Moreover, the biscuit production line can achieve the desired effect in any combination according to the user's site requirements and biscuit process requirements. If you want to develop biscuit business. You can consult us about food machinery at any time. And we will give you the first time reply.

In addition, after using the biscuit production line. You should pay attention to the cleaning of the mechanical equipment. You need to remove the filter regularly for cleaning. However, it should be noted that you must wait until the body is completely cooled before cleaning. If necessary, use a brush to gently scrub the filter. Keep the machine clean and hygienic at all times to make the produced biscuits taste the best and sell the best!

- Telephone+86 18905316466

- Email[email protected]

- WhatsApp+86 18963063440

- WeChat18905316466

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan